Page 182 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 182

Be st Practice 3 .13 Compressor Best Practices

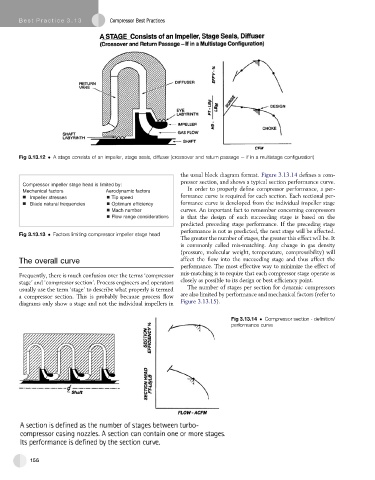

Fig 3.13.12 A stage consists of an impeller, stage seals, diffuser (crossover and return passage e if in a multistage configuration)

the usual block diagram format. Figure 3.13.14 defines a com-

pressor section, and shows a typical section performance curve.

Compressor impeller stage head is limited by:

In order to properly define compressor performance, a per-

Mechanical factors Aerodynamic factors

formance curve is required for each section. Each sectional per-

Impeller stresses Tip speed

Blade natural frequencies Optimum efficiency formance curve is developed from the individual impeller stage

Mach number curves. An important fact to remember concerning compressors

Flow range considerations is that the design of each succeeding stage is based on the

predicted preceding stage performance. If the preceding stage

performance is not as predicted, the next stage will be affected.

Fig 3.13.13 Factors limiting compressor impeller stage head

The greater the number of stages, the greater this effect will be. It

is commonly called mis-matching. Any change in gas density

(pressure, molecular weight, temperature, compressibility) will

The overall curve affect the flow into the succeeding stage and thus affect the

performance. The most effective way to minimize the effect of

mis-matching is to require that each compressor stage operate as

Frequently, there is much confusion over the terms ‘compressor

stage’ and ‘compressor section’. Process engineers and operators closely as possible to its design or best efficiency point.

The number of stages per section for dynamic compressors

usually use the term ‘stage’ to describe what properly is termed

a compressor section. This is probably because process flow are also limited by performance and mechanical factors (refer to

diagrams only show a stage and not the individual impellers in Figure 3.13.15).

Fig 3.13.14 Compressor section - definition/

performance curve

156