Page 187 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 187

Compressor Best Practices Best Practice 3 .14

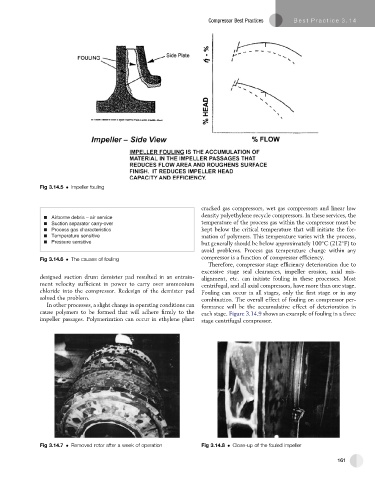

Fig 3.14.5 Impeller fouling

cracked gas compressors, wet gas compressors and linear low

density polyethylene recycle compressors. In these services, the

Airborne debris – air service

Suction separator carry-over temperature of the process gas within the compressor must be

Process gas characteristics kept below the critical temperature that will initiate the for-

Temperature sensitive mation of polymers. This temperature varies with the process,

Pressure sensitive but generally should be below approximately 100 C (212 F) to

avoid problems. Process gas temperature change within any

Fig 3.14.6 The causes of fouling compressor is a function of compressor efficiency.

Therefore, compressor stage efficiency deterioration due to

excessive stage seal clearances, impeller erosion, axial mis-

designed suction drum demister pad resulted in an entrain- alignment, etc. can initiate fouling in these processes. Most

ment velocity sufficient in power to carry over ammonium centrifugal, and all axial compressors, have more than one stage.

chloride into the compressor. Redesign of the demister pad Fouling can occur in all stages, only the first stage or in any

solved the problem. combination. The overall effect of fouling on compressor per-

In other processes, a slight change in operating conditions can formance will be the accumulative effect of deterioration in

cause polymers to be formed that will adhere firmly to the each stage. Figure 3.14.9 shows an example of fouling in a three

impeller passages. Polymerization can occur in ethylene plant stage centrifugal compressor.

Fig 3.14.7 Removed rotor after a week of operation Fig 3.14.8 Close-up of the fouled impeller

161