Page 220 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 220

Be st Practice 3 .22 Compressor Best Practices

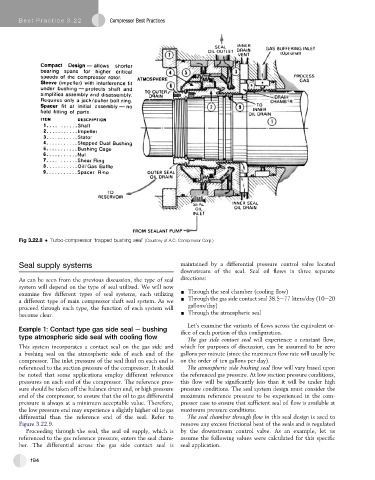

Fig 3.22.8 Turbo-compressor ‘trapped bushing seal’ (Courtesy of A.C. Compressor Corp.)

Seal supply systems maintained by a differential pressure control valve located

downstream of the seal. Seal oil flows in three separate

As can be seen from the previous discussion, the type of seal directions:

system will depend on the type of seal utilized. We will now

examine five different types of seal systems, each utilizing - Through the seal chamber (cooling flow)

a different type of main compressor shaft seal system. As we - Through the gas side contact seal 38.5e77 liters/day (10e20

proceed through each type, the function of each system will gallons/day)

become clear. - Through the atmospheric seal

Let’s examine the variants of flows across the equivalent or-

Example 1: Contact type gas side seal e bushing

ifice of each portion of this configuration.

type atmospheric side seal with cooling flow The gas side contact seal will experience a constant flow,

This system incorporates a contact seal on the gas side and which for purposes of discussion, can be assumed to be zero

a bushing seal on the atmospheric side of each end of the gallons per minute (since the maximum flow rate will usually be

compressor. The inlet pressure of the seal fluid on each end is on the order of ten gallons per day).

referenced to the suction pressure of the compressor. It should The atmospheric side bushing seal flow will vary based upon

be noted that some applications employ different reference the referenced gas pressure. At low suction pressure conditions,

pressures on each end of the compressor. The reference pres- this flow will be significantly less than it will be under high

sure should be taken off the balance drum end, or high pressure pressure conditions. The seal system design must consider the

end of the compressor, to ensure that the oil to gas differential maximum reference pressure to be experienced in the com-

pressure is always at a minimum acceptable value. Therefore, pressor case to ensure that sufficient seal oil flow is available at

the low pressure end may experience a slightly higher oil to gas maximum pressure conditions.

differential than the reference end of the seal. Refer to The seal chamber through flow in this seal design is used to

Figure 3.22.9. remove any excess frictional heat of the seals and is regulated

Proceeding through the seal, the seal oil supply, which is by the downstream control valve. As an example, let us

referenced to the gas reference pressure, enters the seal cham- assume the following values were calculated for this specific

ber. The differential across the gas side contact seal is seal application.

194