Page 301 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 301

Be st Practice 5 .6 Steam Turbine Best Practices

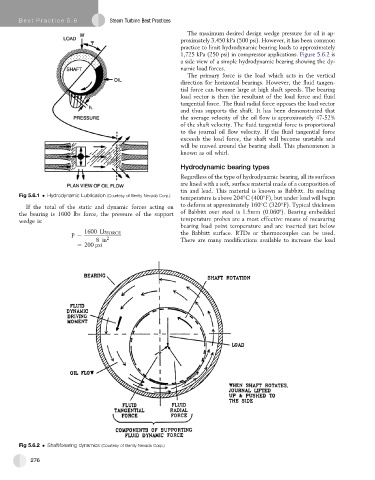

The maximum desired design wedge pressure for oil is ap-

proximately 3,450 kPa (500 psi). However, it has been common

practice to limit hydrodynamic bearing loads to approximately

1,725 kPa (250 psi) in compressor applications. Figure 5.6.2 is

a side view of a simple hydrodynamic bearing showing the dy-

namic load forces.

The primary force is the load which acts in the vertical

direction for horizontal bearings. However, the fluid tangen-

tial force can become large at high shaft speeds. The bearing

load vector is then the resultant of the load force and fluid

tangential force. The fluid radial force opposes the load vector

and thus supports the shaft. It has been demonstrated that

the average velocity of the oil flow is approximately 47-52%

of the shaft velocity. The fluid tangential force is proportional

to the journal oil flow velocity. If the fluid tangential force

exceeds the load force, the shaft will become unstable and

will be moved around the bearing shell. This phenomenon is

known as oil whirl.

Hydrodynamic bearing types

Regardless of the type of hydrodynamic bearing, all its surfaces

are lined with a soft, surface material made of a composition of

tin and lead. This material is known as Babbitt. Its melting

Fig 5.6.1 Hydrodynamic Lubrication (Courtesy of Bently Nevada Corp.)

temperature is above 204 C (400 F), but under load will begin

If the total of the static and dynamic forces acting on to deform at approximately 160 C(320 F). Typical thickness

of Babbitt over steel is 1.5mm (0.060"). Bearing embedded

the bearing is 1600 lbs force, the pressure of the support

wedge is: temperatureprobesare amost effectivemeans of measuring

bearing load point temperature and are inserted just below

1600 Lb FORCE the Babbitt surface. RTDs or thermocouples can be used.

P ¼ 2

8in There are many modifications available to increase the load

¼ 200 psi

Fig 5.6.2 Shaft/bearing dynamics (Courtesy of Bently Nevada Corp.)

276