Page 491 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 491

Be st Practice 7 .36 Lube, Seal and Control Oil System Best Practices

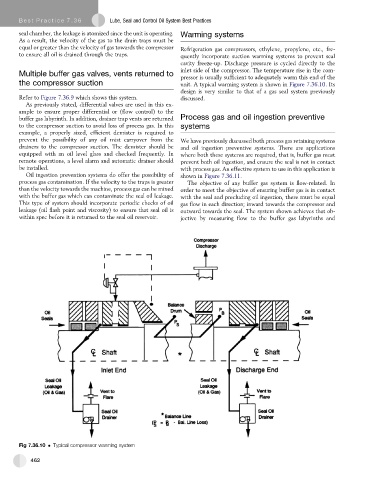

seal chamber, the leakage is atomized since the unit is operating. Warming systems

As a result, the velocity of the gas to the drain traps must be

equal or greater than the velocity of gas towards the compressor Refrigeration gas compressors, ethylene, propylene, etc., fre-

to ensure all oil is drained through the traps. quently incorporate suction warming systems to prevent seal

cavity freeze-up. Discharge pressure is cycled directly to the

inlet side of the compressor. The temperature rise in the com-

Multiple buffer gas valves, vents returned to

pressor is usually sufficient to adequately warm this end of the

the compressor suction unit. A typical warming system is shown in Figure 7.36.10. Its

design is very similar to that of a gas seal system previously

Refer to Figure 7.36.9 which shows this system. discussed.

As previously stated, differential valves are used in this ex-

ample to ensure proper differential or (flow control) to the

buffer gas labyrinth. In addition, drainer trap vents are returned Process gas and oil ingestion preventive

to the compressor suction to avoid loss of process gas. In this systems

example, a properly sized, efficient demister is required to

prevent the possibility of any oil mist carryover from the We have previously discussed both process gas retaining systems

drainers to the compressor suction. The demister should be and oil ingestion preventive systems. There are applications

equipped with an oil level glass and checked frequently. In where both these systems are required, that is, buffer gas must

remote operations, a level alarm and automatic drainer should prevent both oil ingestion, and ensure the seal is not in contact

be installed. with process gas. An effective system to use in this application is

Oil ingestion prevention systems do offer the possibility of shown in Figure 7.36.11.

process gas contamination. If the velocity to the traps is greater The objective of any buffer gas system is flow-related. In

than the velocity towards the machine, process gas can be mixed order to meet the objective of ensuring buffer gas is in contact

with the buffer gas which can contaminate the seal oil leakage. with the seal and precluding oil ingestion, there must be equal

This type of system should incorporate periodic checks of oil gas flow in each direction; inward towards the compressor and

leakage (oil flash point and viscosity) to ensure that seal oil is outward towards the seal. The system shown achieves that ob-

within spec before it is returned to the seal oil reservoir. jective by measuring flow to the buffer gas labyrinths and

Fig 7.36.10 Typical compressor warming system

462