Page 489 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 489

Be st Practice 7 .36 Lube, Seal and Control Oil System Best Practices

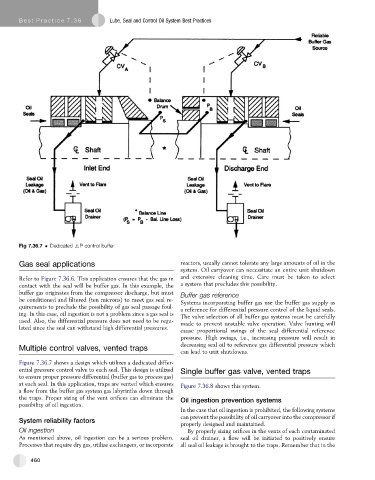

Fig 7.36.7 Dedicated 6P control buffer

Gas seal applications reactors, usually cannot tolerate any large amounts of oil in the

system. Oil carryover can necessitate an entire unit shutdown

Refer to Figure 7.36.6. This application ensures that the gas in and extensive cleaning time. Care must be taken to select

contact with the seal will be buffer gas. In this example, the a system that precludes this possibility.

buffer gas originates from the compressor discharge, but must Buffer gas reference

be conditioned and filtered (ten microns) to meet gas seal re- Systems incorporating buffer gas use the buffer gas supply as

quirements to preclude the possibility of gas seal passage foul- a reference for differential pressure control of the liquid seals.

ing. In this case, oil ingestion is not a problem since a gas seal is The valve selection of all buffer gas systems must be carefully

used. Also, the differential pressure does not need to be regu- made to prevent unstable valve operation. Valve hunting will

lated since the seal can withstand high differential pressures.

cause proportional swings of the seal differential reference

pressure. High swings, i.e., increasing pressure will result in

decreasing seal oil to reference gas differential pressure which

Multiple control valves, vented traps

can lead to unit shutdowns.

Figure 7.36.7 shows a design which utilizes a dedicated differ-

ential pressure control valve to each seal. This design is utilized Single buffer gas valve, vented traps

to ensure proper pressure differential (buffer gas to process gas)

at each seal. In this application, traps are vented which ensures Figure 7.36.8 shows this system.

a flow from the buffer gas system gas labyrinths down through

the traps. Proper sizing of the vent orifices can eliminate the Oil ingestion prevention systems

possibility of oil ingestion.

In the case that oil ingestion is prohibited, the following systems

can prevent the possibility of oil carryover into the compressor if

System reliability factors

properly designed and maintained.

Oil ingestion By properly sizing orifices in the vents of each contaminated

As mentioned above, oil ingestion can be a serious problem. seal oil drainer, a flow will be initiated to positively ensure

Processes that require dry gas, utilize exchangers, or incorporate all seal oil leakage is brought to the traps. Remember that in the

460