Page 485 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 485

Be st Practice 7 .36 Lube, Seal and Control Oil System Best Practices

Best Practice 7.36Practice 7.36Practice 7.36

Best

Best

Use clean, sweet, buffer gas whenever process gas is sour Lessons Learned

and/or can contain debris to optimize oil seal MTBF (in Failure to design for and use a sweet and clean buffer gas

excess of 120 months). in oil seal systems has resulted in low seal MTBFs (less

The entrance of sour gas and/or gas with debris into the oil seal than 12 months) and has caused gas releases in plants that

system will expose the seal oil system to the following issues that can have caused fires and personnel harm.

reduce seal MTBF, cause unscheduled shutdowns and pose a safety

I have known of a case of loss of life that was caused by an internal

hazard (gas release to the plant environment):

valve oil drainer remaining open in sour gas service, which released

Mechanical or iso carbon inner seal hang up and high seal oil H 2 S to the plant while an operator was checking seal oil leakage from

leakage this drainer.

Blockage of internal seal oil drainer orifices causing ingestion of seal

oil into the compressor Benchmarks

Contamination of overhead seal oil tanks with oil sludge, eventually

This best practice has been used and recommended for new projects

blocking internal seal oil ports and exposing the seals to low or zero and plant modifications, since the above incident occurred in the late

seal oil to gas differential and possible gas release to the plant

1970s, to ensure plant safety and optimize seal oil system reliability.

The use of a sweet and clean buffer gas will positively eliminate the

above problems to optimize the life of the seals and the reliability of the

seal system and corresponding unit (99.7% þ).

In this section, we will concentrate only on compressor buffer

B.P. 7.36. Supporting Material

systems.

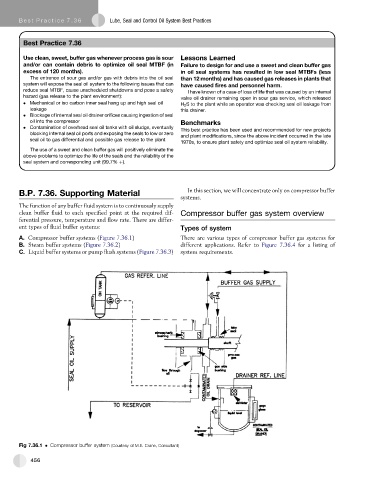

The function of any buffer fluid system is to continuously supply

clean buffer fluid to each specified point at the required dif- Compressor buffer gas system overview

ferential pressure, temperature and flow rate. There are differ-

ent types of fluid buffer systems: Types of system

A. Compressor buffer systems (Figure 7.36.1) There are various types of compressor buffer gas systems for

B. Steam buffer systems (Figure 7.36.2) different applications. Refer to Figure 7.36.4 for a listing of

C. Liquid buffer systems or pump flush systems (Figure 7.36.3) system requirements.

Fig 7.36.1 Compressor buffer system (Courtesy of M.E. Crane, Consultant)

456