Page 480 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 480

Lube, Seal and Control Oil System Best Practices Best Practice 7 .34

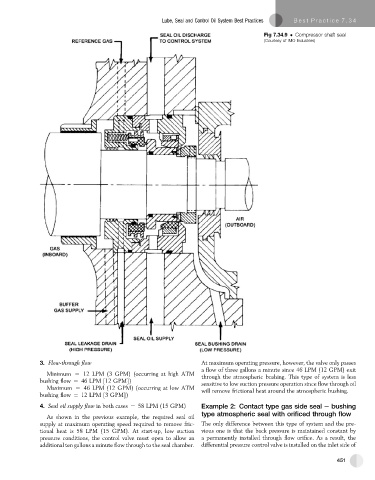

Fig 7.34.9 Compressor shaft seal

(Courtesy of IMO Industries)

At maximum operating pressure, however, the valve only passes

3. Flow-through flow

a flow of three gallons a minute since 46 LPM (12 GPM) exit

Minimum ¼ 12 LPM (3 GPM) (occurring at high ATM

through the atmospheric bushing. This type of system is less

bushing flow ¼ 46 LPM [12 GPM]) sensitive to low suction pressure operation since flow through oil

Maximum ¼ 46 LPM (12 GPM) (occurring at low ATM will remove frictional heat around the atmospheric bushing.

bushing flow ¼ 12 LPM [3 GPM])

4. Seal oil supply flow in both cases ¼ 58 LPM (15 GPM) Example 2: Contact type gas side seal e bushing

type atmospheric seal with orificed through flow

As shown in the previous example, the required seal oil

supply at maximum operating speed required to remove fric- The only difference between this type of system and the pre-

tional heat is 58 LPM (15 GPM). At start-up, low suction vious one is that the back pressure is maintained constant by

pressure conditions, the control valve must open to allow an a permanently installed through flow orifice. As a result, the

additional ten gallons a minute flow through to the seal chamber. differential pressure control valve is installed on the inlet side of

451