Page 478 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 478

Lube, Seal and Control Oil System Best Practices Best Practice 7 .34

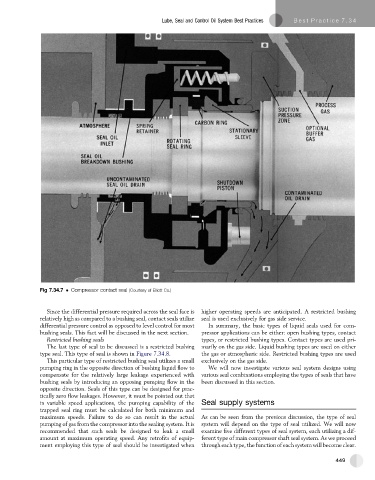

Fig 7.34.7 Compressor contact seal (Courtesy of Elliott Co.)

Since the differential pressure required across the seal face is higher operating speeds are anticipated. A restricted bushing

relatively high as compared to a bushing seal, contact seals utilize seal is used exclusively for gas side service.

differential pressure control as opposed to level control for most In summary, the basic types of liquid seals used for com-

bushing seals. This fact will be discussed in the next section. pressor applications can be either: open bushing types, contact

types, or restricted bushing types. Contact types are used pri-

Restricted bushing seals

The last type of seal to be discussed is a restricted bushing marily on the gas side. Liquid bushing types are used on either

type seal. This type of seal is shown in Figure 7.34.8. the gas or atmospheric side. Restricted bushing types are used

This particular type of restricted bushing seal utilizes a small exclusively on the gas side.

pumping ring in the opposite direction of bushing liquid flow to We will now investigate various seal system designs using

compensate for the relatively large leakage experienced with various seal combinations employing the types of seals that have

bushing seals by introducing an opposing pumping flow in the been discussed in this section.

opposite direction. Seals of this type can be designed for prac-

tically zero flow leakages. However, it must be pointed out that

in variable speed applications, the pumping capability of the Seal supply systems

trapped seal ring must be calculated for both minimum and

maximum speeds. Failure to do so can result in the actual As can be seen from the previous discussion, the type of seal

pumping of gas from the compressor into the sealing system. It is system will depend on the type of seal utilized. We will now

recommended that such seals be designed to leak a small examine five different types of seal system, each utilizing a dif-

amount at maximum operating speed. Any retrofits of equip- ferent type of main compressor shaft seal system. As we proceed

ment employing this type of seal should be investigated when through each type, the function of each system will become clear.

449