Page 483 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 483

Be st Practice 7 .34 Lube, Seal and Control Oil System Best Practices

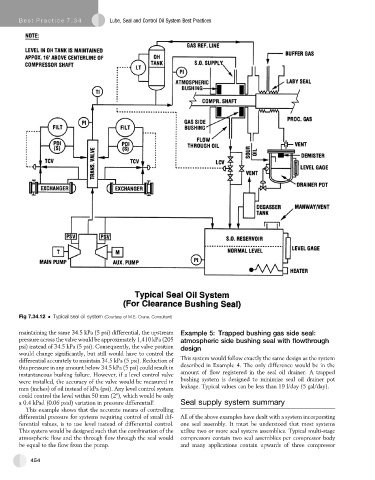

Fig 7.34.12 Typical seal oil system (Courtesy of M.E. Crane, Consultant)

maintaining the same 34.5 kPa (5 psi) differential, the upstream Example 5: Trapped bushing gas side seal:

pressure across the valve would be approximately 1,410 kPa (205 atmospheric side bushing seal with flowthrough

psi) instead of 34.5 kPa (5 psi). Consequently, the valve position design

would change significantly, but still would have to control the

differential accurately to maintain 34.5 kPa (5 psi). Reduction of This system would follow exactly the same design as the system

this pressure in any amount below 34.5 kPa (5 psi) could result in described in Example 4. The only difference would be in the

instantaneous bushing failure. However, if a level control valve amount of flow registered in the seal oil drainer. A trapped

were installed, the accuracy of the valve would be measured in bushing system is designed to minimize seal oil drainer pot

mm (inches) of oil instead of kPa (psi). Any level control system leakage. Typical values can be less than 19 l/day (5 gal/day).

could control the level within 50 mm (2"), which would be only

a 0.4 kPad (0.06 psid) variation in pressure differential! Seal supply system summary

This example shows that the accurate means of controlling

differential pressure for systems requiring control of small dif- All of the above examples have dealt with a system incorporating

ferential values, is to use level instead of differential control. one seal assembly. It must be understood that most systems

This system would be designed such that the combination of the utilize two or more seal system assemblies. Typical multi-stage

atmospheric flow and the through flow through the seal would compressors contain two seal assemblies per compressor body

be equal to the flow from the pump. and many applications contain upwards of three compressor

454