Page 481 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 481

Be st Practice 7 .34 Lube, Seal and Control Oil System Best Practices

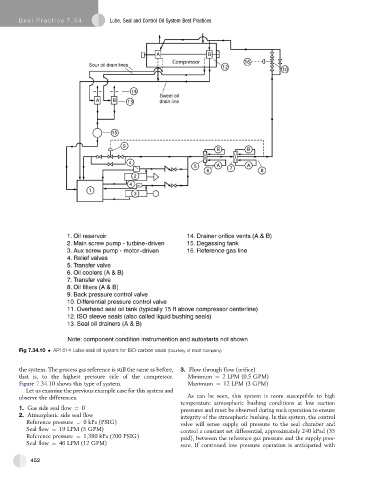

Fig 7.34.10 API 614 Lube-seal oil system for ISO-carbon seals (Courtesy of Elliott Company)

the system. The process gas reference is still the same as before, 3. Flow through flow (orifice)

that is, to the highest pressure side of the compressor. Minimum ¼ 2 LPM (0.5 GPM)

Figure 7.34.10 shows this type of system. Maximum ¼ 12 LPM (3 GPM)

Let us examine the previous example case for this system and

observe the differences. As can be seen, this system is more susceptible to high

temperature atmospheric bushing conditions at low suction

1. Gas side seal flow ¼ 0 pressures and must be observed during such operation to ensure

2. Atmospheric side seal flow integrity of the atmospheric bushing. In this system, the control

Reference pressure ¼ 0 kPa (PSIG) valve will sense supply oil pressure to the seal chamber and

Seal flow ¼ 19 LPM (5 GPM) control a constant set differential, approximately 240 kPad (35

Reference pressure ¼ 1,380 kPa (200 PSIG) psid), between the reference gas pressure and the supply pres-

Seal flow ¼ 46 LPM (12 GPM) sure. If continued low pressure operation is anticipated with

452