Page 527 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 527

Be st Practice 8 .12 Pump Mechanical Seal Flush Best Practices

B.P. 8.12. Supporting Material sure. In addition, as the process side seal leaks in this flush plan,

the atmospheric side seal will essentially be sealing the pumped

fluid, exposing the plant to the release of flammable and/or toxic

API Flush Plan 52

vapors.

Monitoring of seal leaks can be done by checking the level and

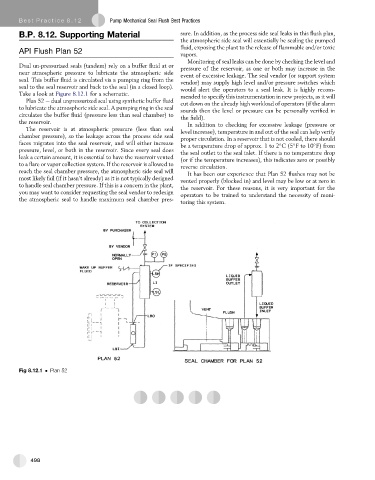

Dual un-pressurized seals (tandem) rely on a buffer fluid at or pressure of the reservoir, as one or both may increase in the

near atmospheric pressure to lubricate the atmospheric side event of excessive leakage. The seal vendor (or support system

seal. This buffer fluid is circulated via a pumping ring from the vendor) may supply high level and/or pressure switches which

seal to the seal reservoir and back to the seal (in a closed loop). would alert the operators to a seal leak. It is highly recom-

Take a look at Figure 8.12.1 for a schematic. mended to specify this instrumentation in new projects, as it will

Plan 52 e dual unpressurized seal using synthetic buffer fluid cut down on the already high workload of operators (if the alarm

to lubricate the atmospheric side seal. A pumping ring in the seal sounds then the level or pressure can be personally verified in

circulates the buffer fluid (pressure less than seal chamber) to

the field).

the reservoir. In addition to checking for excessive leakage (pressure or

The reservoir is at atmospheric pressure (less than seal

level increase), temperature in and out of the seal can help verify

chamber pressure), so the leakage across the process side seal proper circulation. In a reservoir that is not cooled, there should

faces migrates into the seal reservoir, and will either increase be a temperature drop of approx. 1 to 2 C(5 Fto10 F) from

pressure, level, or both in the reservoir. Since every seal does the seal outlet to the seal inlet. If there is no temperature drop

leak a certain amount, it is essential to have the reservoir vented (or if the temperature increases), this indicates zero or possibly

to a flare or vapor collection system. If the reservoir is allowed to reverse circulation.

reach the seal chamber pressure, the atmospheric side seal will It has been our experience that Plan 52 flushes may not be

most likely fail (if it hasn’t already) as it is not typically designed vented properly (blocked in) and level may be low or at zero in

to handle seal chamber pressure. If this is a concern in the plant, the reservoir. For these reasons, it is very important for the

you may want to consider requesting the seal vendor to redesign operators to be trained to understand the necessity of moni-

the atmospheric seal to handle maximum seal chamber pres-

toring this system.

Fig 8.12.1 Plan 52

498