Page 523 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 523

Be st Practice 8 .11 Pump Mechanical Seal Flush Best Practices

B.P. 8.11. Supporting Material

Decreased Pump Flow:

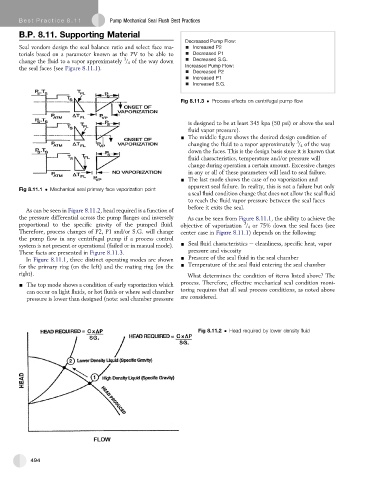

Seal vendors design the seal balance ratio and select face ma- Increased P2

terials based on a parameter known as the PV to be able to Decreased P1

3

change the fluid to a vapor approximately / 4 of the way down Decreased S.G.

the seal faces (see Figure 8.11.1). Increased Pump Flow:

Decreased P2

Increased P1

Increased S.G.

Fig 8.11.3 Process effects on centrifugal pump flow

is designed to be at least 345 kpa (50 psi) or above the seal

fluid vapor pressure).

- The middle figure shows the desired design condition of

3

changing the fluid to a vapor approximately / 4 of the way

down the faces. This is the design basis since it is known that

fluid characteristics, temperature and/or pressure will

change during operation a certain amount. Excessive changes

in any or all of these parameters will lead to seal failure.

- The last mode shows the case of no vaporization and

apparent seal failure. In reality, this is not a failure but only

Fig 8.11.1 Mechanical seal primary face vaporization point

a seal fluid condition change that does not allow the seal fluid

to reach the fluid vapor pressure between the seal faces

before it exits the seal.

As can be seen in Figure 8.11.2, head required is a function of

the pressure differential across the pump flanges and inversely As can be seen from Figure 8.11.1, the ability to achieve the

3

proportional to the specific gravity of the pumped fluid. objective of vaporization / 4 or 75% down the seal faces (see

Therefore, process changes of P2, P1 and/or S.G. will change center case in Figure 8.11.1) depends on the following:

the pump flow in any centrifugal pump if a process control

system is not present or operational (failed or in manual mode). - Seal fluid characteristics e cleanliness, specific heat, vapor

pressure and viscosity

These facts are presented in Figure 8.11.3.

In Figure 8.11.1, three distinct operating modes are shown - Pressure of the seal fluid in the seal chamber

for the primary ring (on the left) and the mating ring (on the - Temperature of the seal fluid entering the seal chamber

right). What determines the condition of items listed above? The

- The top mode shows a condition of early vaporization which process. Therefore, effective mechanical seal condition moni-

can occur on light fluids, or hot fluids or where seal chamber toring requires that all seal process conditions, as noted above

pressure is lower than designed (note: seal chamber pressure are considered.

Fig 8.11.2 Head required by lower density fluid

494