Page 519 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 519

Be st Practice 8 .8 Pump Mechanical Seal Flush Best Practices

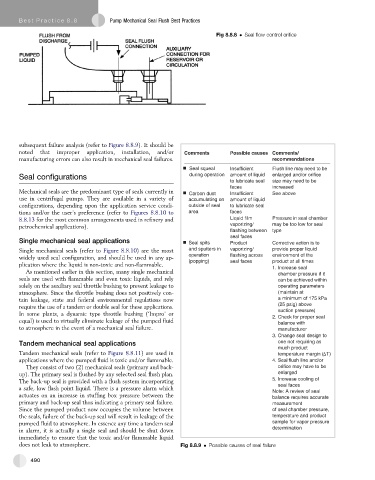

Fig 8.8.8 Seal flow control orifice

subsequent failure analysis (refer to Figure 8.8.9). It should be

noted that improper application, installation, and/or Comments Possible causes Comments/

manufacturing errors can also result in mechanical seal failures. recommendations

Seal squeal Insufficient Flush line may need to be

Seal configurations during operation amount of liquid enlarged and/or orifice

to lubricate seal size may need to be

faces increased

Mechanical seals are the predominant type of seals currently in Carbon dust Insufficient See above

use in centrifugal pumps. They are available in a variety of accumulating on amount of liquid

configurations, depending upon the application service condi- outside of seal to lubricate seal

tions and/or the user’s preference (refer to Figures 8.8.10 to area faces

8.8.13 for the most common arrangements used in refinery and Liquid film Pressure in seal chamber

petrochemical applications). vaporizing/ may be too low for seal

flashing between type

seal faces

Single mechanical seal applications Seal spits Product Corrective action is to

Single mechanical seals (refer to Figure 8.8.10) are the most and sputters in vaporizing/ provide proper liquid

widely used seal configuration, and should be used in any ap- operation flashing across environment of the

(popping)

seal faces

product at all times

plication where the liquid is non-toxic and non-flammable.

1. Increase seal

As mentioned earlier in this section, many single mechanical chamber pressure if it

seals are used with flammable and even toxic liquids, and rely can be achieved within

solely on the auxiliary seal throttle bushing to prevent leakage to operating parameters

atmosphere. Since the throttle bushing does not positively con- (maintain at

tain leakage, state and federal environmental regulations now a minimum of 175 kPa

require the use of a tandem or double seal for these applications. (25 psig) above

suction pressure)

In some plants, a dynamic type throttle bushing (‘Impro’ or 2. Check for proper seal

equal) is used to virtually eliminate leakage of the pumped fluid balance with

to atmosphere in the event of a mechanical seal failure. manufacturer

3. Change seal design to

Tandem mechanical seal applications one not requiring as

much product

Tandem mechanical seals (refer to Figure 8.8.11) are used in temperature margin ( T)

applications where the pumped fluid is toxic and/or flammable. 4. Seal flush line and/or

They consist of two (2) mechanical seals (primary and back- orifice may have to be

up). The primary seal is flushed by any selected seal flush plan. enlarged

The back-up seal is provided with a flush system incorporating 5. Increase cooling of

seal faces

a safe, low flash point liquid. There is a pressure alarm which Note: A review of seal

actuates on an increase in stuffing box pressure between the balance requires accurate

primary and back-up seal thus indicating a primary seal failure. measurement

Since the pumped product now occupies the volume between of seal chamber pressure,

the seals, failure of the back-up seal will result in leakage of the temperature and product

pumped fluid to atmosphere. In essence any time a tandem seal sample for vapor pressure

in alarm, it is actually a single seal and should be shut down determination

immediately to ensure that the toxic and/or flammable liquid

does not leak to atmosphere. Fig 8.8.9 Possible causes of seal failure

490