Page 515 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 515

Be st Practice 8 .7 Pump Mechanical Seal Flush Best Practices

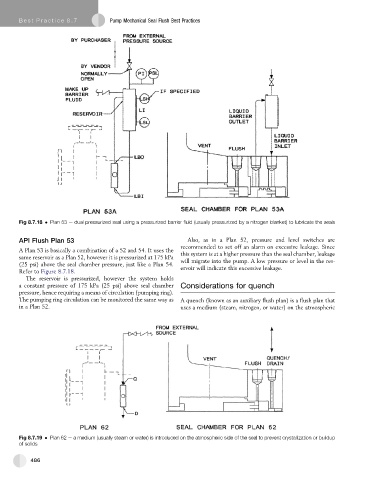

Fig 8.7.18 Plan 53 e dual pressurized seal using a pressurized barrier fluid (usually pressurized by a nitrogen blanket) to lubricate the seals

API Flush Plan 53 Also, as in a Plan 52, pressure and level switches are

recommended to set off an alarm on excessive leakage. Since

A Plan 53 is basically a combination of a 52 and 54. It uses the

same reservoir as a Plan 52, however it is pressurized at 175 kPa this system is at a higher pressure than the seal chamber, leakage

will migrate into the pump. A low pressure or level in the res-

(25 psi) above the seal chamber pressure, just like a Plan 54.

Refer to Figure 8.7.18. ervoir will indicate this excessive leakage.

The reservoir is pressurized, however the system holds

a constant pressure of 175 kPa (25 psi) above seal chamber Considerations for quench

pressure, hence requiring a means of circulation (pumping ring).

The pumping ring circulation can be monitored the same way as A quench (known as an auxiliary flush plan) is a flush plan that

in a Plan 52. uses a medium (steam, nitrogen, or water) on the atmospheric

Fig 8.7.19 Plan 62 e a medium (usually steam or water) is introduced on the atmospheric side of the seal to prevent crystallization or buildup

of solids

486