Page 512 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 512

Pump Mechanical Seal Flush Best Practices Be st Practice 8.7

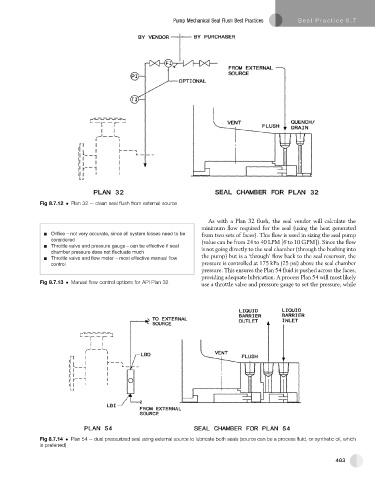

Fig 8.7.12 Plan 32 e clean seal flush from external source

As with a Plan 32 flush, the seal vendor will calculate the

minimum flow required for the seal (using the heat generated

Ori fi ce – not very accurate, since all system losses need to be from two sets of faces). This flow is used in sizing the seal pump

considered (value can be from 24 to 40 LPM [6 to 10 GPM]). Since the flow

Throttle valve and pressure gauge – can be effective if seal

is not going directly to the seal chamber (through the bushing into

chamber pressure does not fl uctuate much

Throttle valve and fl ow meter – most effective manual fl ow the pump) but is a ‘through’ flow back to the seal reservoir, the

control pressure is controlled at 175 kPa (25 psi) above the seal chamber

pressure. This ensures the Plan 54 fluid is pushed across the faces,

providing adequate lubrication. A process Plan 54 will most likely

Fig 8.7.13 Manual flow control options for API Plan 32 use a throttle valve and pressure gauge to set the pressure, while

Fig 8.7.14 Plan 54 e dual pressurized seal using external source to lubricate both seals (source can be a process fluid, or synthetic oil, which

is preferred)

483