Page 516 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 516

Pump Mechanical Seal Flush Best Practices Be st Practice 8.8

side of the seal to wash away any solid buildup from the faces.

The buildup is drained to a collection system. Refer to Using information in this section (or other source), discuss

Figure 8.7.19 for a schematic. parameters to monitor on different fl ush plans

A quench is most commonly used in single seals with steam as Walk to the equipment and monitor these parameters

the medium, if the seal fluid is hot and can form coke particles Discuss action plans to be executed to increase reliability of

and/or if the seal fluid is flammable or toxic. Note: many these systems

Remember, operators see this equipment every day; the more

countries today require dual (tandem or double) seals if the seal they understand about fl ush system, the more reliable the seals

fluid is flammable or toxic, in order to meet environmental re- will be

quirements. The steam should be regulated to a pressure of

approx. 20 to 33 kPa (3 to 5 psi), which is just enough to wash

the accumulated solids off the atmospheric side of the faces. It is Fig 8.7.20 Flush system training for operators

essential for the steam to be superheated (dry), to prevent

flashing of water at the faces, causing premature failures and to vapor. We recommend that an ‘oil condition bottle’, to monitor

ensure that moisture does not enter the bearing chamber. We water in the oil, always be installed in the bearing housings when

have experienced plant fires that resulted from water contami- a steam or water quench is used. Finally, refer to Figure 8.7.20,

nation in the bearing housing, leading to a hot bearing, which highlighting the importance of operator training on flush

served as an ignition source for a single seal leaking a flammable systems.

Best

Best Practice 8.8Practice 8.8

Use medium pressure steam in seal jackets for hot pump Lessons Learned

(above 300 C) services to cool the seal fluid during oper- Low seal MTBFs have been experienced in hot services

ation and keep standby pump seal fluid warm. (bottoms and gas oil) caused by incompatible external

Most hot pump services (bottoms and gas oil refinery services) use flushes (too high a vapor pressure) or failure of the standby

bellows seals (to eliminate the dynamic secondary seal) and dead pump seal during start-up.

ended (no flush) configurations to minimize ingress of fluid particles

This best practice solves both issues by eliminating the need for an

into the seal chamber.

external flush as well as ensuring the seal fluid in the standby pump

As a result, seal chamber jacket cooling is required during

chamber will be at an acceptable viscosity under start-up conditions.

operation.

Medium pressure steam in the seal chamber jacket has proven to Benchmarks

be the best solution in this case, since it will provide adequate cooling This best practice has been used since the mid-1970s to optimize

during operation and keep the seal fluid viscosity in the standby pump refinery bottoms and gas oil pump mechanical seal MTBFs (greater

(frequently on auto-start in these applications) at an acceptable level to than 36 months).

prevent excessive seal wear during start-up and operation.

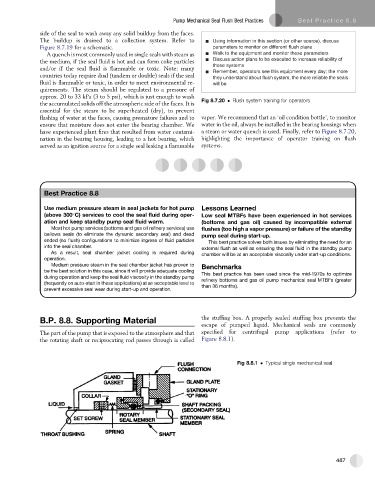

B.P. 8.8. Supporting Material the stuffing box. A properly sealed stuffing box prevents the

escape of pumped liquid. Mechanical seals are commonly

The part of the pump that is exposed to the atmosphere and that specified for centrifugal pump applications (refer to

the rotating shaft or reciprocating rod passes through is called Figure 8.8.1).

Fig 8.8.1 Typical single mechanical seal

487