Page 517 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 517

Be st Practice 8 .8 Pump Mechanical Seal Flush Best Practices

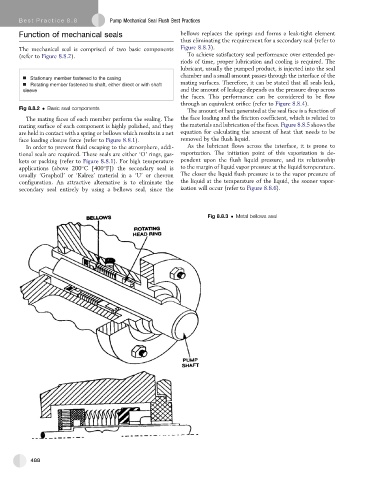

Function of mechanical seals bellowsreplacesthe springsand forms a leak-tight element

thus eliminating the requirement for a secondary seal (refer to

The mechanical seal is comprised of two basic components Figure 8.8.3).

(refer to Figure 8.8.2). To achieve satisfactory seal performance over extended pe-

riods of time, proper lubrication and cooling is required. The

lubricant, usually the pumped product, is injected into the seal

chamber and a small amount passes through the interface of the

Stationary member fastened to the casing

Rotating member fastened to shaft, either direct or with shaft mating surfaces. Therefore, it can be stated that all seals leak,

sleeve and the amount of leakage depends on the pressure drop across

the faces. This performance can be considered to be flow

through an equivalent orifice (refer to Figure 8.8.4).

Fig 8.8.2 Basic seal components

The amount of heat generated at the seal face is a function of

The mating faces of each member perform the sealing. The the face loading and the friction coefficient, which is related to

mating surface of each component is highly polished, and they the materials and lubrication of the faces. Figure 8.8.5 shows the

are held in contact with a spring or bellows which results in a net equation for calculating the amount of heat that needs to be

face loading closure force (refer to Figure 8.8.1). removed by the flush liquid.

In order to prevent fluid escaping to the atmosphere, addi- As the lubricant flows across the interface, it is prone to

tional seals are required. These seals are either ‘O’ rings, gas- vaporization. The initiation point of this vaporization is de-

kets or packing (refer to Figure 8.8.1). For high temperature pendent upon the flush liquid pressure, and its relationship

applications (above 200 C [400 F]) the secondary seal is to the margin of liquid vapor pressure at the liquid temperature.

usually ‘Graphoil’ or ‘Kalrez’ material in a ‘U’ or chevron The closer the liquid flush pressure is to the vapor pressure of

configuration. An attractive alternative is to eliminate the the liquid at the temperature of the liquid, the sooner vapor-

secondary seal entirely by using a bellows seal, since the ization will occur (refer to Figure 8.8.6).

Fig 8.8.3 Metal bellows seal

488