Page 520 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 520

Pump Mechanical Seal Flush Best Practices Be st Practice 8.8

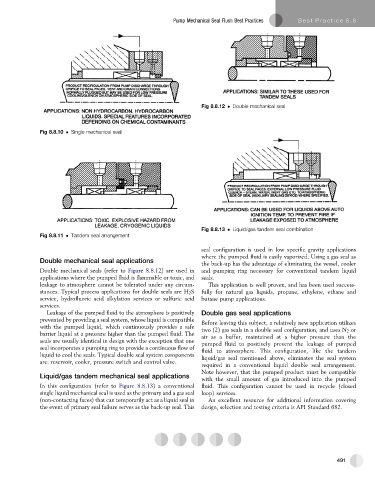

Fig 8.8.12 Double mechanical seal

Fig 8.8.10 Single mechanical seal

Fig 8.8.13 Liquid/gas tandem seal combination

Fig 8.8.11 Tandem seal arrangement

seal configuration is used in low specific gravity applications

where the pumped fluid is easily vaporized. Using a gas seal as

Double mechanical seal applications

the back-up has the advantage of eliminating the vessel, cooler

Double mechanical seals (refer to Figure 8.8.12) are used in and pumping ring necessary for conventional tandem liquid

applications where the pumped fluid is flammable or toxic, and seals.

leakage to atmosphere cannot be tolerated under any circum- This application is well proven, and has been used success-

stances. Typical process applications for double seals are H 2 S fully for natural gas liquids, propane, ethylene, ethane and

service, hydrofluoric acid alkylation services or sulfuric acid butane pump applications.

services.

Leakage of the pumped fluid to the atmosphere is positively Double gas seal applications

prevented by providing a seal system, whose liquid is compatible Before leaving this subject, a relatively new application utilizes

with the pumped liquid, which continuously provides a safe two (2) gas seals in a double seal configuration, and uses N 2 or

barrier liquid at a pressure higher than the pumped fluid. The air as a buffer, maintained at a higher pressure than the

seals are usually identical in design with the exception that one pumped fluid to positively prevent the leakage of pumped

seal incorporates a pumping ring to provide a continuous flow of fluid to atmosphere. This configuration, like the tandem

liquid to cool the seals. Typical double seal system components liquid/gas seal mentioned above, eliminates the seal system

are: reservoir, cooler, pressure switch and control valve.

required in a conventional liquid double seal arrangement.

Note however, that the pumped product must be compatible

Liquid/gas tandem mechanical seal applications

with the small amount of gas introduced into the pumped

In this configuration (refer to Figure 8.8.13) a conventional fluid. This configuration cannot be used in recycle (closed

single liquid mechanical seal is used as the primary and a gas seal loop) services.

(non-contacting faces) that can temporarily act as a liquid seal in An excellent resource for additional information covering

the event of primary seal failure serves as the back-up seal. This design, selection and testing criteria is API Standard 682.

491