Page 518 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 518

Pump Mechanical Seal Flush Best Practices Be st Practice 8.8

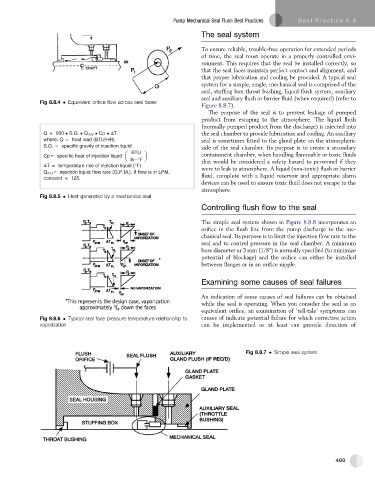

The seal system

To ensure reliable, trouble-free operation for extended periods

of time, the seal must operate in a properly controlled envi-

ronment. This requires that the seal be installed correctly, so

that the seal faces maintain perfect contact and alignment, and

that proper lubrication and cooling be provided. A typical seal

system for a simple, single, mechanical seal is comprised of the

seal, stuffing box throat bushing, liquid flush system, auxiliary

seal and auxiliary flush or barrier fluid (when required) (refer to

Fig 8.8.4 Equivalent orifice flow across seal faces

Figure 8.8.7).

The purpose of the seal is to prevent leakage of pumped

product from escaping to the atmosphere. The liquid flush

(normally pumped product from the discharge) is injected into

Q = 500 S.G. Q, NJ Cp T the seal chamber to provide lubrication and cooling. An auxiliary

where: Q = heat load (BTU/HR) seal is sometimes fitted to the gland plate on the atmospheric

S.G. = specific gravity of injection liquid side of the seal chamber. Its purpose is to create a secondary

Cp = specific heat of injection liquid containment chamber, when handling flammable or toxic fluids

lb °F that would be considered a safety hazard to personnel if they

T = temperature rise of injection liquid (°F)

were to leak to atmosphere. A liquid (non-toxic) flush or barrier

Q INJ = injection liquid flow rate (G.P.M.). If flow is in LPM,

constant = 125. fluid, complete with a liquid reservoir and appropriate alarm

devices can be used to ensure toxic fluid does not escape to the

atmosphere.

Fig 8.8.5 Heat generated by a mechanical seal

Controlling flush flow to the seal

The simple seal system shown in Figure 8.8.8 incorporates an

orifice in the flush line from the pump discharge to the me-

chanical seal. Its purpose is to limit the injection flow rate to the

seal and to control pressure in the seal chamber. A minimum

bore diameter or 3 mm (1/8") is normally specified (to minimize

potential of blockage) and the orifice can either be installed

between flanges or in an orifice nipple.

Examining some causes of seal failures

An indication of some causes of seal failures can be obtained

while the seal is operating. When you consider the seal as an

equivalent orifice, an examination of ‘tell-tale’ symptoms can

Fig 8.8.6 Typical seal face pressure temperature relationship to causes of indicate potential failure for which corrective action

vaporization can be implemented or at least can provide direction of

Fig 8.8.7 Simple seal system

489