Page 522 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 522

Pump Mechanical Seal Flush Best Practices Best Practice 8 .11

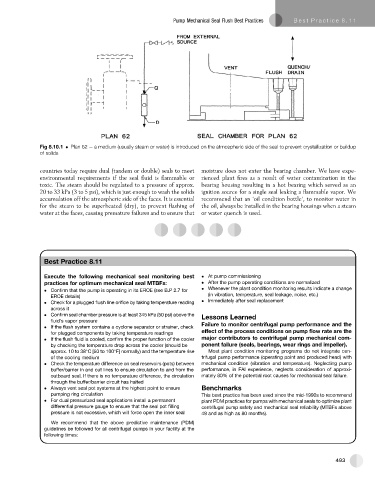

Fig 8.10.1 Plan 62 e a medium (usually steam or water) is introduced on the atmospheric side of the seal to prevent crystallization or buildup

of solids

countries today require dual (tandem or double) seals to meet moisture does not enter the bearing chamber. We have expe-

environmental requirements if the seal fluid is flammable or rienced plant fires as a result of water contamination in the

toxic. The steam should be regulated to a pressure of approx. bearing housing resulting in a hot bearing which served as an

20 to 33 kPa (3 to 5 psi), which is just enough to wash the solids ignition source for a single seal leaking a flammable vapor. We

accumulation off the atmospheric side of the faces. It is essential recommend that an ‘oil condition bottle’, to monitor water in

for the steam to be superheated (dry), to prevent flashing of the oil, always be installed in the bearing housings when a steam

water at the faces, causing premature failures and to ensure that or water quench is used.

Best

Best Practice 8.11Practice 8.11Practice 8.11

Best

Execute the following mechanical seal monitoring best At pump commissioning

practices for optimum mechanical seal MTBFs: After the pump operating conditions are normalized

Confirm that the pump is operating in its EROE (see B.P 2.7 for Whenever the plant condition monitoring results indicate a change

EROE details) (in vibration, temperature, seal leakage, noise, etc.)

Check for a plugged flush line orifice by taking temperature reading Immediately after seal replacement

across it

Confirm seal chamber pressure is at least 345 kPa (50 psi) above the Lessons Learned

fluid’s vapor pressure

Failure to monitor centrifugal pump performance and the

If the flush system contains a cyclone separator or strainer, check

effect of the process conditions on pump flow rate are the

for plugged components by taking temperature readings

If the flush fluid is cooled, confirm the proper function of the cooler major contributors to centrifugal pump mechanical com-

by checking the temperature drop across the cooler (should be ponent failure (seals, bearings, wear rings and impeller).

approx. 10 to 38 C [50 to 100 F] normally) and the temperature rise Most plant condition monitoring programs do not integrate cen-

of the cooling medium trifugal pump performance (operating point and produced head) with

Check the temperature difference on seal reservoirs (pots) between mechanical condition (vibration and temperature). Neglecting pump

buffer/barrier in and out lines to ensure circulation to and from the performance, in FAI experience, neglects consideration of approxi-

outboard seal. If there is no temperature difference, the circulation mately 80% of the potential root causes for mechanical seal failure.

through the buffer/barrier circuit has halted

Always vent seal pot systems at the highest point to ensure Benchmarks

pumping ring circulation This best practice has been used since the mid-1990s to recommend

For dual pressurized seal applications install a permanent plant PDM practices for pumps with mechanical seals to optimize plant

differential pressure gauge to ensure that the seal pot filling centrifugal pump safety and mechanical seal reliability (MTBFs above

pressure is not excessive, which will force open the inner seal 48 and as high as 80 months).

We recommend that the above predictive maintenance (PDM)

guidelines be followed for all centrifugal pumps in your facility at the

following times:

493