Page 532 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 532

Dry Gas Seal Best Practices Be st Practice 9.1

used in a large plant of high daily revenue (greater than $1 MM/ compressor were retrofitted for a gas seal. WOW! What a dif-

day). ference. Why are there such a small number of components for

The reliability of critical equipment is dependent on the re- the gas seal system? As an aid, refer to Figure 9.1.4, which shows

liability of each component in every auxiliary system connected a typical pump liquid flush system as specified by the American

with the critical equipment unit. How do we maximize critical Petroleum Institute. This system incorporates a liquid me-

equipment reliability? The easiest way is to eliminate the aux- chanical seal and utilizes pump discharge liquid as a flush for the

iliary systems. Imagine the opportunity to eliminate all of the seal. Refer now to Figure 9.1.3 and observe the similarities. It

components; pumps, filters, reservoirs, etc. and thereby increase should be evident that a gas seal system is simplified in com-

reliability and hopefully, the safety of the equipment. The gas pressor applications over a liquid seal system, merely because

seal as used in compressor applications affords the opportunity the gas seal utilizes the process fluid. This is exactly the same

to achieve these objectives. However, the gas seal is still part of case for a pump. By using the process fluid, and not a liquid, one

a system and the entire gas seal system must be properly spec- can eliminate the need to separate liquid from a gas, thereby

ified, designed, maintained and operated to achieve the objec- totally eliminating the need for a liquid supply system and the

tives of optimum safety and reliability of the critical equipment. need for a contaminated liquid (sour oil) drain system.

In this section, the principles of gas seal design will be Referring back to Figure 9.1.2, therefore, we can see that the

discussed and applied to various gas seal system types. In addi- following major components are eliminated:

tion, best practices will be discussed for saturated gas systems as

well as shutdown philosophies. 1. The seal oil reservoir

2. The pumping units

3. The exchangers

System function 4. The temperature control valves

5. The overhead tank

The function of a gas seal system is naturally the same as a liquid 6. The drain pot

seal system. The function of a fluid seal system, remembering that 7. The degassing tank

a fluid can be a liquid or a gas, is to continuously supply clean fluid 8. All control valves

to each specified seal interface point at the required differential 9. A significant amount of instrumentation

pressure, temperature, and flow rate. Therefore, one would Referring back to the function definition of the gas seal system,

expect the design of a gas seal and a liquid seal to be very similar, all requirements are met. ‘Continuously supplying fluid’ is

which, in fact, they are. Then why are their systems so different?

achieved by utilizing the discharge pressure of the compressor.

The requirements for ‘specified differential pressure, tempera-

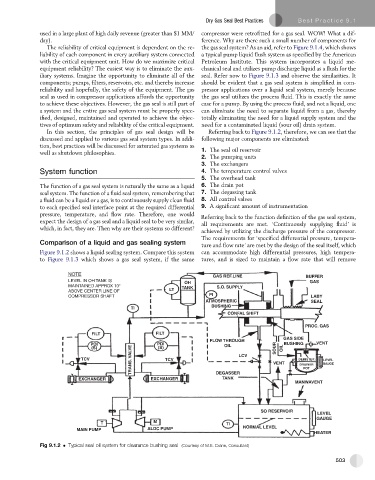

Comparison of a liquid and gas sealing system ture and flow rate’ are met by the design of the seal itself, which

Figure 9.1.2 shows a liquid sealing system. Compare this system can accommodate high differential pressures, high tempera-

to Figure 9.1.3 which shows a gas seal system, if the same tures, and is sized to maintain a flow rate that will remove

NOTE GAS REF.LINE BUFFER

LEVEL IN OH TANK IS OH GAS

MAINTAINED APPROX 10° TANK S.O. SUPPLY

ABOVE CENTER LINE OF LT

COMPRESSOR SHAFT PI LABY

ATMOSPHERIC SEAL

BUSHING

TI

CONFAL SHIFT

PROC. GAS

FILT FILT

GAS SIDE

FLOW THROUGH

PDI PDI OIL BUSHING VENT

TRANS. VALVE VENT DEMISTER GAUGE

(S) (S) SOUR OIL

TCV TCV LCV

LEVEL

DRAINER

POT

TANK

EXCHANGER EXCHANGER DEGASSER

MANWAVENT

SO RESERVOIR

LEVEL

GAUGE

T M TI

MAIN PUMP ALDC PUMP NORMAL LEVEL

HEATER

Fig 9.1.2 Typical seal oil system for clearance bushing seal (Courtesy of M.E. Crane, Consultant)

503