Page 533 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 533

Be st Practice 9 .1 Dry Gas Seal Best Practices

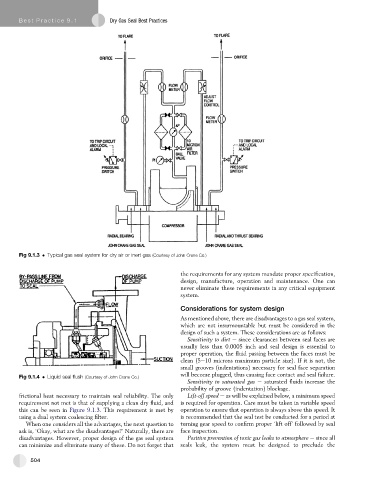

Fig 9.1.3 Typical gas seal system for dry air or inert gas (Courtesy of John Crane Co.)

the requirements for any system mandate proper specification,

design, manufacture, operation and maintenance. One can

never eliminate these requirements in any critical equipment

system.

Considerations for system design

As mentioned above, there are disadvantages to a gas seal system,

which are not insurmountable but must be considered in the

design of such a system. These considerations are as follows:

Sensitivity to dirt e since clearances between seal faces are

usually less than 0.0005 inch and seal design is essential to

proper operation, the fluid passing between the faces must be

clean (5e10 microns maximum particle size). If it is not, the

small grooves (indentations) necessary for seal face separation

will become plugged, thus causing face contact and seal failure.

Fig 9.1.4 Liquid seal flush (Courtesy of John Crane Co.)

Sensitivity to saturated gas e saturated fluids increase the

probability of groove (indentation) blockage.

frictional heat necessary to maintain seal reliability. The only Lift-off speed e as will be explained below, a minimum speed

requirement not met is that of supplying a clean dry fluid, and is required for operation. Care must be taken in variable speed

this can be seen in Figure 9.1.3. This requirement is met by operation to ensure that operation is always above this speed. It

using a dual system coalescing filter. is recommended that the seal test be conducted for a period at

When one considers all the advantages, the next question to turning gear speed to confirm proper ‘lift off’ followed by seal

ask is, ‘Okay, what are the disadvantages?’ Naturally, there are face inspection.

disadvantages. However, proper design of the gas seal system Positive prevention of toxic gas leaks to atmosphere e since all

can minimize and eliminate many of these. Do not forget that seals leak, the system must be designed to preclude the

504