Page 556 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 556

The Post-Shipment Phase: Installation, Pre-Commissioning, Commissioning and Start-up Best Practices Best Practice 1 0.1

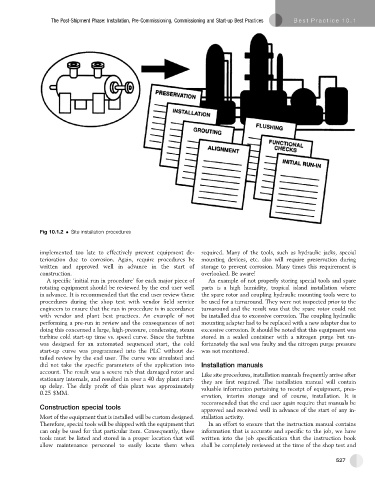

Fig 10.1.2 Site installation procedures

implemented too late to effectively prevent equipment de- required. Many of the tools, such as hydraulic jacks, special

terioration due to corrosion. Again, require procedures be mounting devices, etc. also will require preservation during

written and approved well in advance in the start of storage to prevent corrosion. Many times this requirement is

construction. overlooked. Be aware!

Aspecific ‘initial run in procedure’ for each major piece of An example of not properly storing special tools and spare

rotating equipment should be reviewed by the end user well parts is a high humidity, tropical island installation where

in advance. It is recommended that the end user review these the spare rotor and coupling hydraulic mounting tools were to

procedures during the shop test with vendor field service be used for a turnaround. They were not inspected prior to the

engineers to ensure that the run in procedure is in accordance turnaround and the result was that the spare rotor could not

with vendor and plant best practices. An example of not be installed due to excessive corrosion. The coupling hydraulic

performing a pre-run in review and the consequences of not mounting adapter had to be replaced with a new adapter due to

doing this concerned a large, high-pressure, condensing, steam excessive corrosion. It should be noted that this equipment was

turbine cold start-up time vs. speed curve. Since the turbine stored in a sealed container with a nitrogen purge but un-

was designed for an automated sequenced start, the cold fortunately the seal was faulty and the nitrogen purge pressure

start-up curve was programmed into the PLC without de- was not monitored.

tailed review by the end user. The curve was simulated and

did not take the specific parameters of the application into Installation manuals

account. The result was a severe rub that damaged rotor and Like site procedures, installation manuals frequently arrive after

stationary internals, and resulted in over a 40 day plant start- they are first required. The installation manual will contain

up delay. The daily profit of this plant was approximately valuable information pertaining to receipt of equipment, pres-

0.25 $MM.

ervation, interim storage and of course, installation. It is

recommended that the end user again require that manuals be

Construction special tools

approved and received well in advance of the start of any in-

Most of the equipment that is installed will be custom designed. stallation activity.

Therefore, special tools will be shipped with the equipment that In an effort to ensure that the instruction manual contains

can only be used for that particular item. Consequently, these information that is accurate and specific to the job, we have

tools must be listed and stored in a proper location that will writteninto the jobspecification that the instruction book

allow maintenance personnel to easily locate them when shall be completely reviewed at the time of the shop test and

527