Page 72 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 72

Be st Practice 2 .7 Pump Best Practices

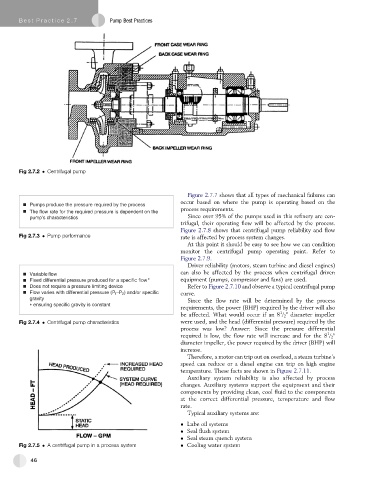

Fig 2.7.2 Centrifugal pump

Figure 2.7.7 shows that all types of mechanical failures can

occur based on where the pump is operating based on the

Pumps produce the pressure required by the process

process requirements.

The flow rate for the required pressure is dependent on the

pump’s characteristics Since over 95% of the pumps used in this refinery are cen-

trifugal, their operating flow will be affected by the process.

Figure 2.7.8 shows that centrifugal pump reliability and flow

Fig 2.7.3 Pump performance rate is affected by process system changes.

At this point it should be easy to see how we can condition

monitor the centrifugal pump operating point. Refer to

Figure 2.7.9.

Driver reliability (motors, steam turbine and diesel engines)

can also be affected by the process when centrifugal driven

Variable flow

Fixed differential pressure produced for a specific flow ∗ equipment (pumps, compressor and fans) are used.

Does not require a pressure limiting device Refer to Figure 2.7.10 and observe a typical centrifugal pump

Flow varies with differential pressure (P 1 –P 2 ) and/or specific curve.

gravity Since the flow rate will be determined by the process

∗ ensuring specific gravity is constant

requirements, the power (BHP) required by the driver will also

1

be affected. What would occur if an 8 / 2 " diameter impeller

Fig 2.7.4 Centrifugal pump characteristics were used, and the head (differential pressure) required by the

process was low? Answer: Since the pressure differential

1

required is low, the flow rate will increase and for the 8 / 2 "

diameter impeller, the power required by the driver (BHP) will

increase.

Therefore, a motor can trip out on overload, a steam turbine’s

speed can reduce or a diesel engine can trip on high engine

temperature. These facts are shown in Figure 2.7.11.

Auxiliary system reliability is also affected by process

changes. Auxiliary systems support the equipment and their

components by providing clean, cool fluid to the components

at the correct differential pressure, temperature and flow

rate.

Typical auxiliary systems are:

Lube oil systems

Seal flush system

Seal steam quench system

Fig 2.7.5 A centrifugal pump in a process system Cooling water system

46