Page 75 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 75

Pump Best Practices Be st Practice 2.7

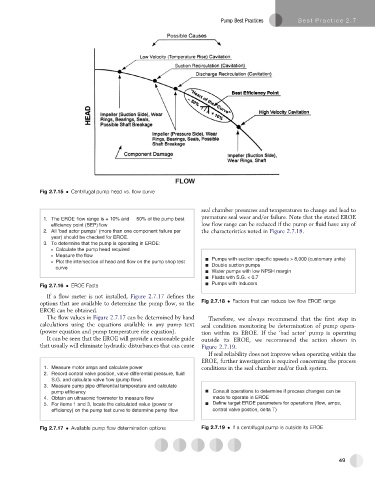

Fig 2.7.15 Centrifugal pump head vs. flow curve

seal chamber pressures and temperatures to change and lead to

premature seal wear and/or failure. Note that the stated EROE

1. The EROE flow range is + 10% and 50% of the pump best

efficiency point (BEP) flow low flow range can be reduced if the pump or fluid have any of

2. All ‘bad actor pumps’ (more than one component failure per the characteristics noted in Figure 2.7.18.

year) should be checked for EROE.

3. To determine that the pump is operating in EROE:

Calculate the pump head required

Measure the flow

Plot the intersection of head and flow on the pump shop test Pumps with suction specific speeds > 8,000 (customary units)

curve Double suction pumps

Water pumps with low NPSH margin

Fluids with S.G. < 0.7

Pumps with Inducers

Fig 2.7.16 EROE Facts

If a flow meter is not installed, Figure 2.7.17 defines the

options that are available to determine the pump flow, so the Fig 2.7.18 Factors that can reduce low flow EROE range

EROE can be obtained.

The flow values in Figure 2.7.17 can be determined by hand Therefore, we always recommend that the first step in

calculations using the equations available in any pump text seal condition monitoring be determination of pump opera-

(power equation and pump temperature rise equation). tion within its EROE. If the ‘bad actor’ pump is operating

It can be seen that the EROE will provide a reasonable guide outside its EROE, we recommend the action shown in

that usually will eliminate hydraulic disturbances that can cause Figure 2.7.19.

If seal reliability does not improve when operating within the

EROE, further investigation is required concerning the process

1. Measure motor amps and calculate power conditions in the seal chamber and/or flush system.

2. Record control valve position, valve differential pressure, fluid

S.G. and calculate valve flow (pump flow).

3. Measure pump pipe differential temperature and calculate

pump efficiency Consult operations to determine if process changes can be

4. Obtain an ultrasonic flowmeter to measure flow made to operate in EROE

5. For items 1 and 3, locate the calculated value (power or Define target EROE parameters for operations (flow, amps,

efficiency) on the pump test curve to determine pump flow control valve postion, delta T)

Fig 2.7.17 Available pump flow determination options Fig 2.7.19 If a centrifugal pump is outside its EROE

49