Page 82 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 82

Be st Practice 2 .11 Pump Best Practices

Best Practice 2.11Practice 2.11Practice 2.11Practice 2.11

Best

Best

Best

Define NPSH margins for the maximum flow point of a cen- Centrifugal pump applications that process liquids with high vapor

trifugal pump to prevent cavitation for all operating cases. pressures are susceptible to low NPSH margins when operating at

Ensure that the NPSH margin is acceptable at the maximum pos- heads less than the rated head. Failure to select the NPSH margin

sible flow, based on the process control system design. considering the installed control and protection system has resulted in

Confirm that the pump is protected, to ensure that there will be reduced pump safety and reliability.

a recirculation margin at minimum operating flow.

Accurately define all liquid characteristics (vapor pressure, viscos- Benchmarks

ity, specific gravity and pumping temperature).

I have used this best practice since 1990 for pumps with a high vapor

pressure (typically specific gravity below 0.7). This best practice has

Lessons Learned resulted in high vapor pressure applications of optimum safety and

Pump NPSH available to NPSH required margins are tra- reliability (MTBFs exceeding 80 months).

ditionally set for only the rated operating point. Centrifugal

pump flow is a result of process system requirements and

the installed process control system.

B.P. 2.11. Supporting Material Care should be taken to define liquid composition and tem-

perature as accurately as possible, since these items will de-

termine the vapor pressure which in turn defines the

Defining the process system NPSH AVAILABLE . The steps for defining the process re-

quirements are summarized in Figure 2.11.2.

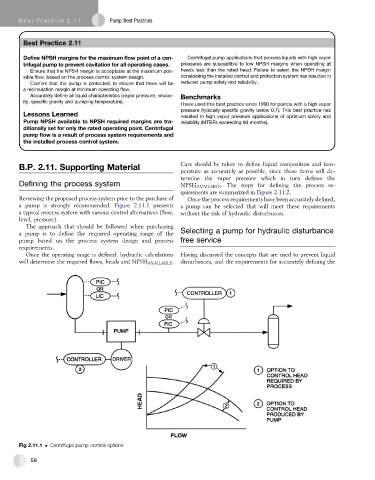

Reviewing the proposed process system prior to the purchase of Once the process requirements have been accurately defined,

a pump is strongly recommended. Figure 2.11.1 presents a pump can be selected that will meet these requirements

a typical process system with various control alternatives (flow, without the risk of hydraulic disturbances.

level, pressure).

The approach that should be followed when purchasing

a pump is to define the required operating range of the Selecting a pump for hydraulic disturbance

pump based on the process system design and process free service

requirements.

Once the operating range is defined, hydraulic calculations Having discussed the concepts that are used to prevent liquid

will determine the required flows, heads and NPSH AVAILABLE . disturbances, and the requirements for accurately defining the

Fig 2.11.1 Centrifugal pump control options

56