Page 361 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 361

1656_C007.fm Page 341 Monday, May 23, 2005 5:54 PM

Fracture Toughness Testing of Metals 341

An investigation of the Liberty ship failures during World War II revealed that fracture was much

more likely in steels with Charpy energy less than 20 J (15 ft-lb).

During the 1950s, when Irwin and his colleagues at the Naval Research Laboratory (NRL)

were formulating the principles of linear elastic fracture mechanics, a metallurgist at NRL named

W.S. Pellini developed the drop weight test, a qualitative measure of crack-arrest toughness.

Both the Charpy test and the Pellini drop weight test are still widely applied today to structural

materials. ASTM has standardized the drop weight tests, as well as a number of related approaches,

including the Izod, drop weight tear and dynamic tear tests [42–45] (see Section 7.9.1). Although

these tests lack the mathematical rigor and predictive capabilities of fracture mechanics methods,

these approaches provide a qualitative indication of material toughness. The advantage of these

qualitative methods is that they are cheaper and easier to perform than fracture mechanics tests.

These tests are suitable for material screening and quality control, but are not reliable indicators

of structural integrity.

7.9.1 CHARPY AND IZOD IMPACT TEST

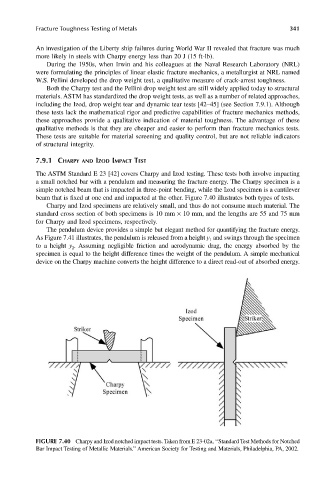

The ASTM Standard E 23 [42] covers Charpy and Izod testing. These tests both involve impacting

a small notched bar with a pendulum and measuring the fracture energy. The Charpy specimen is a

simple notched beam that is impacted in three-point bending, while the Izod specimen is a cantilever

beam that is fixed at one end and impacted at the other. Figure 7.40 illustrates both types of tests.

Charpy and Izod specimens are relatively small, and thus do not consume much material. The

standard cross section of both specimens is 10 mm × 10 mm, and the lengths are 55 and 75 mm

for Charpy and Izod specimens, respectively.

The pendulum device provides a simple but elegant method for quantifying the fracture energy.

As Figure 7.41 illustrates, the pendulum is released from a height y and swings through the specimen

1

to a height y . Assuming negligible friction and aerodynamic drag, the energy absorbed by the

2

specimen is equal to the height difference times the weight of the pendulum. A simple mechanical

device on the Charpy machine converts the height difference to a direct read-out of absorbed energy.

FIGURE 7.40 Charpy and Izod notched impact tests. Taken from E 23-02a, ‘‘Standard Test Methods for Notched

Bar Impact Testing of Metallic Materials.’’ American Society for Testing and Materials, Philadelphia, PA, 2002.