Page 358 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 358

1656_C007.fm Page 338 Monday, May 23, 2005 5:54 PM

338 Fracture Mechanics: Fundamentals and Applications

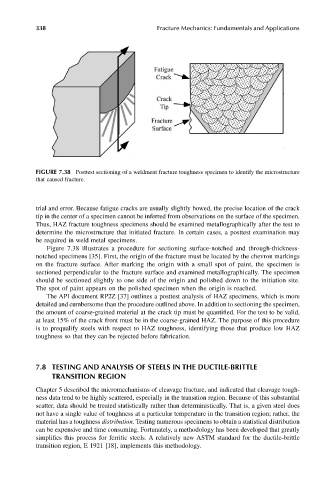

FIGURE 7.38 Posttest sectioning of a weldment fracture toughness specimen to identify the microstructure

that caused fracture.

trial and error. Because fatigue cracks are usually slightly bowed, the precise location of the crack

tip in the center of a specimen cannot be inferred from observations on the surface of the specimen.

Thus, HAZ fracture toughness specimens should be examined metallographically after the test to

determine the microstructure that initiated fracture. In certain cases, a posttest examination may

be required in weld metal specimens.

Figure 7.38 illustrates a procedure for sectioning surface-notched and through-thickness-

notched specimens [35]. First, the origin of the fracture must be located by the chevron markings

on the fracture surface. After marking the origin with a small spot of paint, the specimen is

sectioned perpendicular to the fracture surface and examined metallographically. The specimen

should be sectioned slightly to one side of the origin and polished down to the initiation site.

The spot of paint appears on the polished specimen when the origin is reached.

The API document RP2Z [37] outlines a posttest analysis of HAZ specimens, which is more

detailed and cumbersome than the procedure outlined above. In addition to sectioning the specimen,

the amount of coarse-grained material at the crack tip must be quantified. For the test to be valid,

at least 15% of the crack front must be in the coarse-grained HAZ. The purpose of this procedure

is to prequalify steels with respect to HAZ toughness, identifying those that produce low HAZ

toughness so that they can be rejected before fabrication.

7.8 TESTING AND ANALYSIS OF STEELS IN THE DUCTILE-BRITTLE

TRANSITION REGION

Chapter 5 described the micromechanisms of cleavage fracture, and indicated that cleavage tough-

ness data tend to be highly scattered, especially in the transition region. Because of this substantial

scatter, data should be treated statistically rather than deterministically. That is, a given steel does

not have a single value of toughness at a particular temperature in the transition region; rather, the

material has a toughness distribution. Testing numerous specimens to obtain a statistical distribution

can be expensive and time consuming. Fortunately, a methodology has been developed that greatly

simplifies this process for ferritic steels. A relatively new ASTM standard for the ductile-brittle

transition region, E 1921 [18], implements this methodology.