Page 357 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 357

1656_C007.fm Page 337 Monday, May 23, 2005 5:54 PM

Fracture Toughness Testing of Metals 337

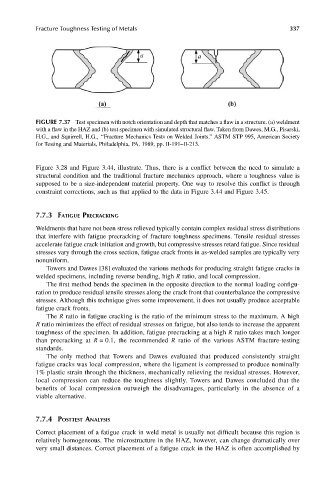

FIGURE 7.37 Test specimen with notch orientation and depth that matches a flaw in a structure. (a) weldment

with a flaw in the HAZ and (b) test specimen with simulated structural flaw. Taken from Dawes, M.G., Pisarski,

H.G., and Squirrell, H.G., ‘‘Fracture Mechanics Tests on Welded Joints.’’ ASTM STP 995, American Society

for Testing and Materials, Philadelphia, PA, 1989, pp. II-191–II-213.

Figure 3.28 and Figure 3.44, illustrate. Thus, there is a conflict between the need to simulate a

structural condition and the traditional fracture mechanics approach, where a toughness value is

supposed to be a size-independent material property. One way to resolve this conflict is through

constraint corrections, such as that applied to the data in Figure 3.44 and Figure 3.45.

7.7.3 FATIGUE PRECRACKING

Weldments that have not been stress relieved typically contain complex residual stress distributions

that interfere with fatigue precracking of fracture toughness specimens. Tensile residual stresses

accelerate fatigue crack initiation and growth, but compressive stresses retard fatigue. Since residual

stresses vary through the cross section, fatigue crack fronts in as-welded samples are typically very

nonuniform.

Towers and Dawes [38] evaluated the various methods for producing straight fatigue cracks in

welded specimens, including reverse bending, high R ratio, and local compression.

The first method bends the specimen in the opposite direction to the normal loading configu-

ration to produce residual tensile stresses along the crack front that counterbalance the compressive

stresses. Although this technique gives some improvement, it does not usually produce acceptable

fatigue crack fronts.

The R ratio in fatigue cracking is the ratio of the minimum stress to the maximum. A high

R ratio minimizes the effect of residual stresses on fatigue, but also tends to increase the apparent

toughness of the specimen. In addition, fatigue precracking at a high R ratio takes much longer

than precracking at R = 0.1, the recommended R ratio of the various ASTM fracture-testing

standards.

The only method that Towers and Dawes evaluated that produced consistently straight

fatigue cracks was local compression, where the ligament is compressed to produce nominally

1% plastic strain through the thickness, mechanically relieving the residual stresses. However,

local compression can reduce the toughness slightly. Towers and Dawes concluded that the

benefits of local compression outweigh the disadvantages, particularly in the absence of a

viable alternative.

7.7.4 POSTTEST ANALYSIS

Correct placement of a fatigue crack in weld metal is usually not difficult because this region is

relatively homogeneous. The microstructure in the HAZ, however, can change dramatically over

very small distances. Correct placement of a fatigue crack in the HAZ is often accomplished by