Page 393 - Fundamentals of Gas Shale Reservoirs

P. 393

DEVELOPMENT PHASE DISCUSSION 373

Avoiding fault zone: Targeting natural Avoiding fracture Targeting natural Eliminate

don’t frac into water fracture swarms swarms from fracture swarms nonproductive

below target horizon maximizes impact adjacent wells maximizes impact stages

of the frac energy frac job of the frac energy

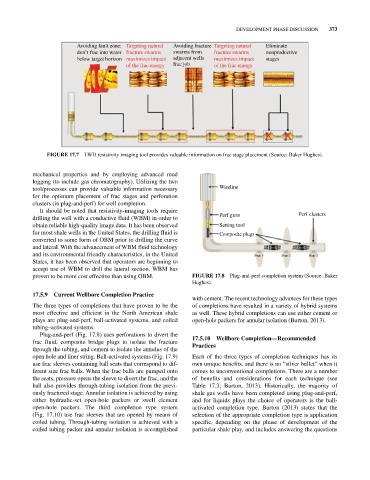

FiguRe 17.7 LWD resistivity imaging tool provides valuable information on frac stage placement (Source: Baker Hughes).

mechanical properties and by employing advanced mud

logging (to include gas chromatography). Utilizing the two

tool/processes can provide valuable information necessary Wireline

for the optimum placement of frac stages and perforation

clusters (in plug‐and‐perf) for well completion.

It should be noted that resistivity‐imaging tools require

drilling the well with a conductive fluid (WBM) in order to Perf guns Perf clusters

obtain reliable high‐quality image data. It has been observed Setting tool

for most shale wells in the United States, the drilling fluid is Composite plugs

converted to some form of OBM prior to drilling the curve

and lateral. With the advancement of WBM fluid technology

and its environmental friendly characteristics, in the United Stage 3 Stage 2 Stage 1

States, it has been observed that operators are beginning to

accept use of WBM to drill the lateral section. WBM has

proven to be more cost effective than using OBM. FiguRe 17.8 Plug‐and‐perf completion system (Source: Baker

Hughes).

17.5.9 Current Wellbore Completion Practice

with cement. The recent technology advances for these types

The three types of completions that have proven to be the of completions have resulted in a variety of hybrid systems

most effective and efficient in the North American shale as well. These hybrid completions can use either cement or

plays are plug‐and‐perf, ball‐activated systems, and coiled open‐hole packers for annular isolation (Burton, 2013).

tubing–activated systems.

Plug‐and‐perf (Fig. 17.8) uses perforations to divert the

frac fluid, composite bridge plugs to isolate the fracture 17.5.10 Wellbore Completion—Recommended

through the tubing, and cement to isolate the annulus of the Practices

open hole and liner string. Ball‐activated systems (Fig. 17.9) Each of the three types of completion techniques has its

use frac sleeves containing ball seats that correspond to dif- own unique benefits, and there is no “silver bullet” when it

ferent size frac balls. When the frac balls are pumped onto comes to unconventional completions. There are a number

the seats, pressure opens the sleeve to divert the frac, and the of benefits and considerations for each technique (see

ball also provides through‐tubing isolation from the previ- Table 17.3; Burton, 2013). Historically, the majority of

ously fractured stage. Annular isolation is achieved by using shale gas wells have been completed using plug‐and‐perf,

either hydraulic‐set open‐hole packers or swell element and for liquids plays the choice of operators is the ball‐

open‐hole packers. The third completion type system activated completion type. Burton (2013) states that the

(Fig. 17.10) use frac sleeves that are opened by means of selection of the appropriate completion type is application

coiled tubing. Through‐tubing isolation is achieved with a specific, depending on the phase of development of the

coiled tubing packer and annular isolation is accomplished particular shale play, and includes answering the questions