Page 394 - Fundamentals of Gas Shale Reservoirs

P. 394

374 GAS SHALE CHALLENGES OVER THE ASSET LIFE CYCLE

Frac sleeves with ball seats

Casing packer

Openhole packers

FIGURE 17.9 Ball‐activated completion system (Source: Baker Hughes).

Frac fluid flow

in annulus

Frac sleeves

Coiled tubing Packer

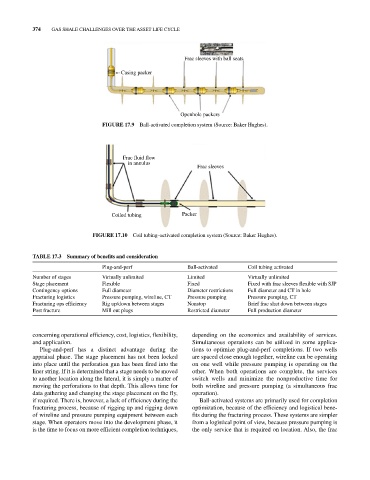

FIGURE 17.10 Coil tubing–activated completion system (Source: Baker Hughes).

TABLE 17.3 Summary of benefits and consideration

Plug‐and‐perf Ball‐activated Coil tubing activated

Number of stages Virtually unlimited Limited Virtually unlimited

Stage placement Flexible Fixed Fixed with frac sleeves flexible with SJP

Contingency options Full diameter Diameter restrictions Full diameter and CT in hole

Fracturing logistics Pressure pumping, wireline, CT Pressure pumping Pressure pumping, CT

Fracturing ops efficiency Rig up/down between stages Nonstop Brief frac shut down between stages

Post fracture Mill out plugs Restricted diameter Full production diameter

concerning operational efficiency, cost, logistics, flexibility, depending on the economics and availability of services.

and application. Simultaneous operations can be utilized in some applica-

Plug‐and‐perf has a distinct advantage during the tions to optimize plug‐and‐perf completions. If two wells

appraisal phase. The stage placement has not been locked are spaced close enough together, wireline can be operating

into place until the perforation gun has been fired into the on one well while pressure pumping is operating on the

liner string. If it is determined that a stage needs to be moved other. When both operations are complete, the services

to another location along the lateral, it is simply a matter of switch wells and minimize the nonproductive time for

moving the perforations to that depth. This allows time for both wireline and pressure pumping (a simultaneous frac

data gathering and changing the stage placement on the fly, operation).

if required. There is, however, a lack of efficiency during the Ball‐activated systems are primarily used for completion

fracturing process, because of rigging up and rigging down optimization, because of the efficiency and logistical bene-

of wireline and pressure pumping equipment between each fits during the fracturing process. These systems are simpler

stage. When operators move into the development phase, it from a logistical point of view, because pressure pumping is

is the time to focus on more efficient completion techniques, the only service that is required on location. Also, the frac