Page 307 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 307

262 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

Impeller flow

Pipe flow

(a) (b)

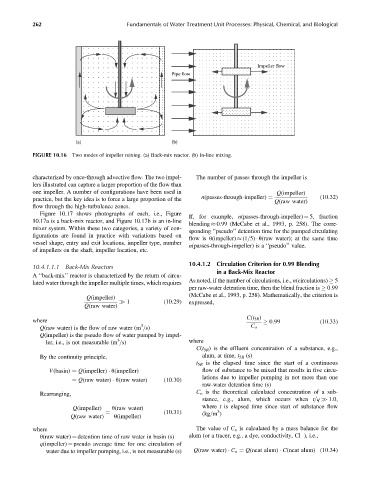

FIGURE 10.16 Two modes of impeller mixing. (a) Back-mix reactor. (b) In-line mixing.

characterized by once-through advective flow. The two impel- The number of passes through the impeller is

lers illustrated can capture a larger proportion of the flow than

one impeller. A number of configurations have been used in Q(impeller)

practice, but the key idea is to force a large proportion of the n(passes-through-impeller) ¼ (10:32)

Q(raw water)

flow through the high-turbulence zones.

Figure 10.17 shows photographs of each, i.e., Figure

If, for example, n(passes-through-impeller) ¼ 5, fraction

10.17a is a back-mix reactor, and Figure 10.17b is an in-line

blending 0.99 (McCabe et al., 1993, p. 258). The corre-

mixer system. Within these two categories, a variety of con-

sponding ‘‘pseudo’’ detention time for the pumped circulating

figurations are found in practice with variations based on

flow is u(impeller) (1=5) u(raw water); at the same time

vessel shape, entry and exit locations, impeller type, number

n(passes-through-impeller) is a ‘‘pseudo’’ value.

of impellers on the shaft, impeller location, etc.

10.4.1.2 Circulation Criterion for 0.99 Blending

10.4.1.1.1 Back-Mix Reactors

in a Back-Mix Reactor

A ‘‘back-mix’’ reactor is characterized by the return of circu-

As noted, if the number of circulations, i.e., n(circulations) 5

lated water through the impeller multiple times, which requires

per raw-water detention time, then the blend fraction is 0.99

(McCabe et al., 1993, p. 258). Mathematically, the criterion is

Q(impeller)

1 (10:29) expressed,

Q(raw water)

C(t 5R )

where 0:99 (10:33)

3

Q(raw water) is the flow of raw water (m =s) C o

Q(impeller) is the pseudo flow of water pumped by impel-

3

ler, i.e., is not measurable (m =s) where

C(t 5R ) is the effluent concentration of a substance, e.g.,

By the continuity principle, alum, at time, t 5R (s)

t 5R is the elapsed time since the start of a continuous

V(basin) ¼ Q(impeller) u(impeller) flow of substance to be mixed that results in five circu-

lations due to impeller pumping in not more than one

¼ Q(raw water) u(raw water) (10:30)

raw-water detention time (s)

Rearranging, C o is the theoretical calculated concentration of a sub-

stance, e.g., alum, which occurs when t=q >> 1.0,

Q(impeller) u(raw water) where t is elapsed time since start of substance flow

(10:31) (kg=m )

3

Q(raw water) u(impeller)

¼

where The value of C o is calculated by a mass balance for the

u(raw water) ¼ detention time of raw water in basin (s) alum (or a tracer, e.g., a dye, conductivity, Cl ), i.e.,

q(impeller) ¼ pseudo average time for one circulation of

water due to impeller pumping, i.e., is not measurable (s) Q(raw water) C o ¼ Q(neat alum) C(neat alum) (10:34)