Page 586 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 586

Membrane Processes 541

(a) (b)

FIGURE 17.2 Two kinds of membrane elements: spiral wound and

hollow fiber. (a) Spiral-wound RO membrane element, 203 mm

(8 in.) diameter 1016 mm (40 in.) long. (Courtesy of Rodney

Evans, James (Ed) Burke, Brighton, CO.) (b) Hollow-fiber mem-

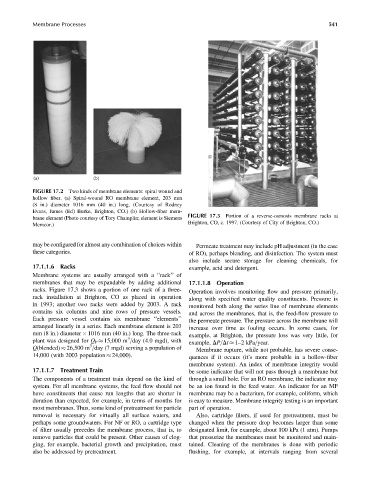

FIGURE 17.3 Portion of a reverse-osmosis membrane racks at

brane element (Photo courtesy of Tory Champlin; element is Siemens

Brighton, CO, c. 1997. (Courtesy of City of Brighton, CO.)

Memcor.)

may be configured for almost any combination of choices within Permeate treatment may include pH adjustment (in the case

these categories. of RO), perhaps blending, and disinfection. The system must

also include secure storage for cleaning chemicals, for

17.1.1.6 Racks example, acid and detergent.

Membrane systems are usually arranged with a ‘‘rack’’ of

membranes that may be expandable by adding additional 17.1.1.8 Operation

racks. Figure 17.3 shows a portion of one rack of a three- Operation involves monitoring flow and pressure primarily,

rack installation at Brighton, CO as placed in operation along with specified water quality constituents. Pressure is

in 1993; another two racks were added by 2003. A rack monitored both along the series line of membrane elements

contains six columns and nine rows of pressure vessels. and across the membranes, that is, the feed-flow pressure to

Each pressure vessel contains six membrane ‘‘elements’’ the permeate pressure. The pressure across the membrane will

arranged linearly in a series. Each membrane element is 203 increase over time as fouling occurs. In some cases, for

mm (8 in.) diameter 1016 mm (40 in.) long. The three-rack example, at Brighton, the pressure loss was very little, for

3

plant was designed for Q P 15,000 m =day (4.0 mgd), with example, DP=Dt 1–2 kPa=year.

3

Q(blended) 26,500 m =day (7 mgd) serving a population of Membrane rupture, while not probable, has severe conse-

14,000 (with 2003 population 24,000). quences if it occurs (it’s more probable in a hollow-fiber

membrane system). An index of membrane integrity would

17.1.1.7 Treatment Train be some indicator that will not pass through a membrane but

The components of a treatment train depend on the kind of through a small hole. For an RO membrane, the indicator may

system. For all membrane systems, the feed flow should not be an ion found in the feed water. An indicator for an MF

have constituents that cause run lengths that are shorter in membrane may be a bacterium, for example, coliform, which

duration than expected, for example, in terms of months for is easy to measure. Membrane integrity testing is an important

most membranes. Thus, some kind of pretreatment for particle part of operation.

removal is necessary for virtually all surface waters, and Also, cartridge filters, if used for pretreatment, must be

perhaps some groundwaters. For NF or RO, a cartridge type changed when the pressure drop becomes larger than some

of filter usually precedes the membrane process, that is, to designated limit, for example, about 100 kPa (1 atm). Pumps

remove particles that could be present. Other causes of clog- that pressurize the membranes must be monitored and main-

ging, for example, bacterial growth and precipitation, must tained. Cleaning of the membranes is done with periodic

also be addressed by pretreatment. flushing, for example, at intervals ranging from several