Page 591 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 591

546 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

Perforated

tube

Leaf

thickness Glued to Leaf width

perforated tube

Perforated

tube

Glued

edges

Membrane Feed water spacer

Permeate water spacer Leaf length Membrane

Membrane Permeate water spacer

Membrane

Feed water spacer

(a) (b)

Plastic Upper fiber

fibers

NOM deposits

elongated in the

direction of flow

Flow path

Top fiber Lower fiber through spacer

layer 1 mm 200kV 2.42E1 0006/22 NO5 p503

NOM deposits

Bottom fiber Feed water Clean

layer flow path surface

Feed water

spacer outline

1 mm 19.9 kV 2.32E1 0012/22 H25P109

(c) (d)

Unwound element

Wound element

8 in. diameter

5

4 1 4 in. diameter

3 2

Five membrane leafs

(e) (f)

End caps with connected

Pressure vessel

feed water plumbing

housings

Experimental membrane

element being inserted

(g) (h)

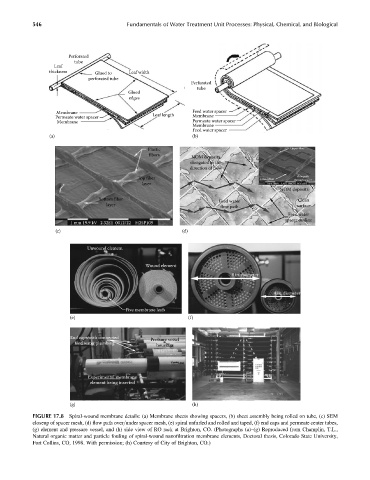

FIGURE 17.8 Spiral-wound membrane details: (a) Membrane sheets showing spacers, (b) sheet assembly being rolled on tube, (c) SEM

closeup of spacer mesh, (d) flow path over=under spacer mesh, (e) spiral unfurled and rolled and taped, (f) end caps and permeate center tubes,

(g) element and pressure vessel, and (h) side view of RO rack at Brighton, CO. (Photographs (a)–(g) Reproduced from Champlin, T.L.,

Natural organic matter and particle fouling of spiral-wound nanofiltration membrane elements, Doctoral thesis, Colorado State University,

Fort Collins, CO, 1998. With permission; (h) Courtesy of City of Brighton, CO.)