Page 69 - Gas Purification 5E

P. 69

Aikanolarnines for lfvdrogen Suwde and Carbon Dioxide Rernoirrl 59

be noted however, that this condensate is saturated with acid gas at regenerator condenser

operating conditions and that this dissolved acid gas will be reintroduced into the gas stream

if the water is used “as is” for wasbing. If the gas volume is very large, compared to the

amount of wash water, this may be of no consequence. However, if calculations indicate that

the quantity of acid gas so introduced is excessive, a water smpper can be included in the

process. Alternatively, a recirculating water wash with a dedicated water wash pump can be

utilized. This design uses a comparatively small wash water make-up and wash watcr purge.

A water wash is used primarily in monoethanolamine systems, especially at low absorber

operating pressures, as the relatively bigh vapor pressure of monoethanolamine may cause

appreciable vaporization losses. The other amines usually have sufficiently low vapor pres-

sures to make water washing unnecessary, except in rare cases when the purified gas is used

in a catalytic process and the catalyst is sensitive even to traces of amine vapors.

The number of trays used for water wash varies from two to five in commercial installa-

tions. Experience has indicated that an efficiency of 40 or 50% can be expected per tray

under typical absorber operating conditions. From this, it would appear that four trays would

be ample to remove over 80% of the vaporized amine from the purified gas and, incidentally,

a major portion of the amine carried as entrained droplets in the gas stream.

It is probable that an even greater tray efficiency is obtained in the water wash section of

the stripping column. However, because of the higher temperature involved, the amine con-

tent of the vapors entering this section may be quite high. Four to six trays are commonIy

used for this service.

Split-Stream Cycles

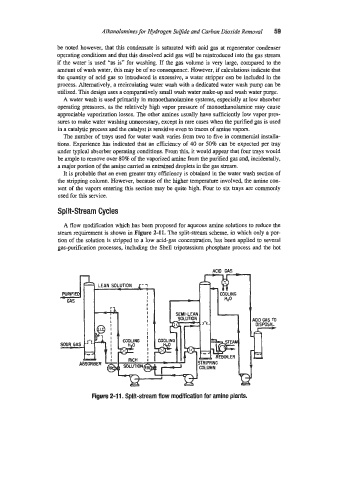

A flow modification which has been proposed for aqueous amine solutions to reduce the

steam mpimnent is shown in Figure 2-11. The split-stream scheme, in which only a por-

tion of the solution is stripped to a low acid-gas concentration, has been applied to several

gas-purification processes, including the Shell tripotassium phosphate process and the hot

ACID GAS

Figure 2-11. Split-stream flow modification for amine plants.