Page 163 - Gas Wettability of Reservoir Rock Surfaces with Porous Media

P. 163

Effect of Gas Wettability on the Surface Properties CHAPTER 4 147

Table 4.15 Element Content in Montmorillonite Surface Before and After

Gas-wetting Treatment

Element Before Treatment After Treatment

Wt% At% Wt% At%

C 0.00 0.00 15.91 25.05

O 36.66 50.02 29.05 34.34

F 0.00 0.00 10.30 10.25

Na 2.44 2.31 1.66 1.37

Mg 3.86 3.47 1.83 1.42

Al 11.81 9.55 7.46 5.23

Si 43.05 33.46 31.76 21.38

Ca 2.18 1.19 2.04 0.96

Wt%, Weight percentage; At%, atomic percentage.

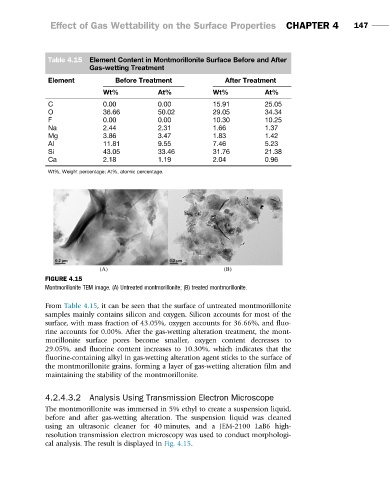

FIGURE 4.15

Montmorillonite TEM image. (A) Untreated montmorillonite; (B) treated montmorillonite.

From Table 4.15, it can be seen that the surface of untreated montmorillonite

samples mainly contains silicon and oxygen. Silicon accounts for most of the

surface, with mass fraction of 43.05%, oxygen accounts for 36.66%, and fluo-

rine accounts for 0.00%. After the gas-wetting alteration treatment, the mont-

morillonite surface pores become smaller, oxygen content decreases to

29.05%, and fluorine content increases to 10.30%, which indicates that the

fluorine-containing alkyl in gas-wetting alteration agent sticks to the surface of

the montmorillonite grains, forming a layer of gas-wetting alteration film and

maintaining the stability of the montmorillonite.

4.2.4.3.2 Analysis Using Transmission Electron Microscope

The montmorillonite was immersed in 5% ethyl to create a suspension liquid,

before and after gas-wetting alteration. The suspension liquid was cleaned

using an ultrasonic cleaner for 40 minutes, and a JEM-2100 LaB6 high-

resolution transmission electron microscopy was used to conduct morphologi-

cal analysis. The result is displayed in Fig. 4.15.