Page 563 - Handbook of Biomechatronics

P. 563

556 Graham Brooker

Force

Fluid film

supports

rotor

Blood

converges

Hydrodynamic

pressure profile

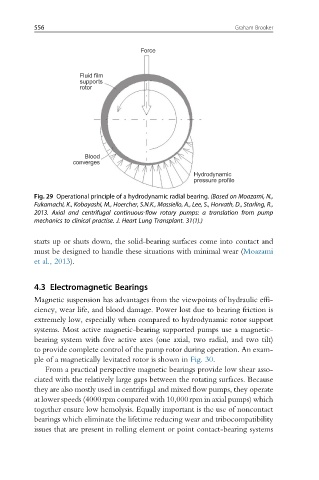

Fig. 29 Operational principle of a hydrodynamic radial bearing. (Based on Moazami, N.,

Fukamachi, K., Kobayashi, M., Hoercher, S.N.K., Massiello, A., Lee, S., Horvath, D., Starling, R.,

2013. Axial and centrifugal continuous-flow rotary pumps: a translation from pump

mechanics to clinical practise. J. Heart Lung Transplant. 31(1).)

starts up or shuts down, the solid-bearing surfaces come into contact and

must be designed to handle these situations with minimal wear (Moazami

et al., 2013).

4.3 Electromagnetic Bearings

Magnetic suspension has advantages from the viewpoints of hydraulic effi-

ciency, wear life, and blood damage. Power lost due to bearing friction is

extremely low, especially when compared to hydrodynamic rotor support

systems. Most active magnetic-bearing supported pumps use a magnetic-

bearing system with five active axes (one axial, two radial, and two tilt)

to provide complete control of the pump rotor during operation. An exam-

ple of a magnetically levitated rotor is shown in Fig. 30.

From a practical perspective magnetic bearings provide low shear asso-

ciated with the relatively large gaps between the rotating surfaces. Because

they are also mostly used in centrifugal and mixed flow pumps, they operate

at lower speeds (4000rpm compared with 10,000rpm in axial pumps) which

together ensure low hemolysis. Equally important is the use of noncontact

bearings which eliminate the lifetime reducing wear and tribocompatibility

issues that are present in rolling element or point contact-bearing systems