Page 192 - Handbook of Civil Engineering Calculations, Second Edition

P. 192

HANGERS, CONNECTORS, AND WIND-STRESS ANALYSIS 1.175

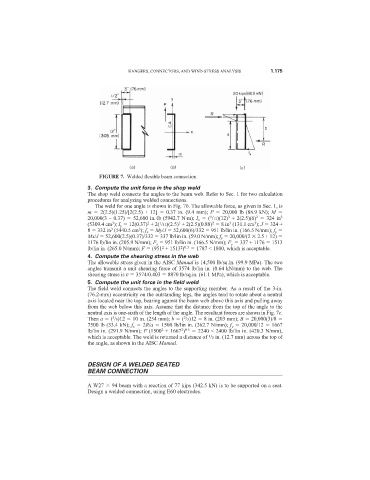

FIGURE 7. Welded flexible beam connection.

3. Compute the unit force in the shop weld

The shop weld connects the angles to the beam web. Refer to Sec. 1 for two calculation

procedures for analyzing welded connections.

The weld for one angle is shown in Fig. 7b. The allowable force, as given in Sec. 1, is

m 2(2.5)(1.25)/[2(2.5) + 12] 0.37 in. (9.4 mm); P 20,000 lb (88.9 kN); M

2

1

3

20,000(3 – 0.37) 52,600 in.·lb (5942.7 N·m); I x ( /12)(12) + 2(2.5)(6) 324 in 3

1

3

2

3

3

3

2

(5309.4 cm ); I y 12(0.37) + 2( /12)(2.5) + 2(2.5)(0.88) 8 in (131.1 cm ); J 324 +

3

8 332 in (5440.5 cm ); f x My/J 52,600(6)/332 951 lb/lin in. (166.5 N/mm); f y

3

Mx/J 52,600(2.5)(0.37)/332 337 lb/lin in. (59.0 N/mm); f y 20,000/(2 2.5 + 12)

1176 lb/lin in. (205.9 N/mm); F x 951 lb/lin in. (166.5 N/mm); F y 337 + 1176 1513

2

2 0.5

lb/lin in. (265.0 N/mm); F (951 + 1513 ) 1787 < 1800, which is acceptable.

4. Compute the shearing stress in the web

The allowable stress given in the AISC Manual is 14,500 lb/sq.in. (99.9 MPa). The two

angles transmit a unit shearing force of 3574 lb/lin in. (0.64 kN/mm) to the web. The

shearing stress is v 3574/0.403 8870 lb/sq.in. (61.1 MPa), which is acceptable.

5. Compute the unit force in the field weld

The field weld connects the angles to the supporting member. As a result of the 3-in.

(76.2-mm) eccentricity on the outstanding legs, the angles tend to rotate about a neutral

axis located near the top, bearing against the beam web above this axis and pulling away

from the web below this axis. Assume that the distance from the top of the angle to the

neutral axis is one-sixth of the length of the angle. The resultant forces are shown in Fig. 7c.

Then a ( /6)12 10 in. (254 mm); b ( /3)12 8 in. (203 mm); B 20,000(3)/8

5

2

7500 lb (33.4 kN); f x 2R/a 1500 lb/lin in. (262.7 N/mm); f y 20,000/12 1667

2 0.5

2

lb/lin in. (291.9 N/mm); F (1500 + 1667 ) 2240 < 2400 lb/lin in. (420.3 N/mm),

1

which is acceptable. The weld is returned a distance of /2 in. (12.7 mm) across the top of

the angle, as shown in the AISC Manual.

DESIGN OF A WELDED SEATED

BEAM CONNECTION

A W27 94 beam with a reaction of 77 kips (342.5 kN) is to be supported on a seat.

Design a welded connection, using E60 electrodes.