Page 197 - Handbook of Civil Engineering Calculations, Second Edition

P. 197

1.180 STRUCTURAL STEEL ENGINEERING AND DESIGN

each member lies 84 in. (2133.6 mm)

from the section of tangency. Design the

knee.

Calculation Procedure:

1. Record the relevant properties

of the members

Refer to the Commentary in the AISC

Manual. The notational system is the

same as that used in the Manual, plus a

distance from section of contraflexure

to section of tangency; b member

flange width; x distance from section

of tangency to given section; M ulti-

mate moment at given section; M p

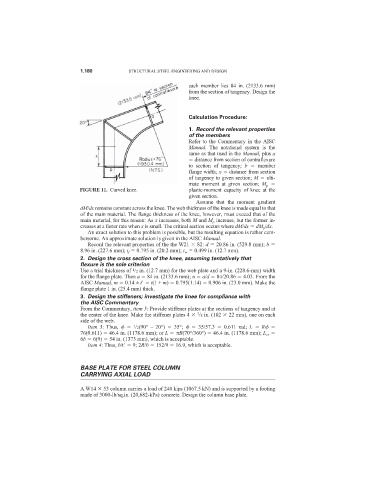

FIGURE 11. Curved knee. plastic-moment capacity of knee at the

given section.

Assume that the moment gradient

dM/dx remains constant across the knee. The web thickness of the knee is made equal to that

of the main material. The flange thickness of the knee, however, must exceed that of the

main material, for this reason: As x increases, both M and M p increase, but the former in-

creases at a faster rate when x is small. The critical section occurs where dM/dx dM p /dx.

An exact solution to this problem is possible, but the resulting equation is rather cum-

bersome. An approximate solution is given in the AISC Manual.

Record the relevant properties of the the W21 82: d 20.86 in. (529.8 mm); b

8.96 in. (227.6 mm); t f 0.795 in. (20.2 mm); t w 0.499 in. (12.7 mm).

2. Design the cross section of the knee, assuming tentatively that

flexure is the sole criterion

1

Use a trial thickness of /2 in. (12.7 mm) for the web plate and a 9-in. (228.6-mm) width

for the flange plate. Then a 84 in. (2133.6 mm); n a/d 84/20.86 4.03. From the

AISC Manual, m 0.14 ± t

t(1 + m) 0.795(1.14) 0.906 in. (23.0 mm). Make the

flange plate 1 in. (25.4 mm) thick.

3. Design the stiffeners; investigate the knee for compliance with

the AISC Commentary

From the Commentary, item 5: Provide stiffener plates at the sections of tangency and at

7

the center of the knee. Make the stiffener plates 4 /8 in. (102 22 mm), one on each

side of the web.

Item 3: Thus, /2(90° – 20°) 35°; 35/57.3 0.611 rad; L R

1

76(0.611) 46.4 in. (1178.6 mm); or L R(70°/360°) 46.4 in. (1178.6 mm); L cr

6b 6(9) 54 in. (1373 mm), which is acceptable.

Item 4: Thus, b/t

9; 2R/b 152/9 16.9, which is acceptable.

BASE PLATE FOR STEEL COLUMN

CARRYING AXIAL LOAD

A W14 53 column carries a load of 240 kips (1067.5 kN) and is supported by a footing

made of 3000-lb/sq.in. (20,682-kPa) concrete. Design the column base plate.