Page 199 - Handbook of Civil Engineering Calculations, Second Edition

P. 199

1.182 STRUCTURAL STEEL ENGINEERING AND DESIGN

Recording the allowable stresses and modular

ratio by using the ACI Code, we get p 750

lb/sq.in. (5170 kPa) and n 9. From the AISC

Specification, f s 14,000 lb/sq.in. (96.5 MPa);

the allowable bending stress in the plate is 27,000

lb/sq.in. (186.1 MPa).

2. Construct the stress

and force diagrams

These are shown in Fig. 13. Then f s /n 14/9

1.555 kips/sq.in. (10.7 MPa); kd 23(0.750/

2.305) 7.48 in. (190.0 mm); jd 23 – 7.48/3

20.51 in. (521.0 mm).

3. Design the base plate

1

Thus, C /2(7.48)(0.750B) 2.805B. Take

moments with respect to the anchor bolt, or M

30(10) + 1100 – 2.805B(20.51) 0; B 24.3

in. (617.2 mm).

Assume that the critical bending stress in the

base plate occurs at the face of the column. Com-

pute the bending moment at the face for a 1-in.

(25.4-mm) width of plate. Referring to Fig. 13c,

we have p

0.750(1.48/7.48) 0.148 kips/sq.in.

(1020.3 kPa); M (6 /6)(0.148 + 2 0.750)

2

2

9.89 in.·kips (1.12 kN·m); t – 6M/27 2.20 sq.in.

2

(14.19 cm ); t 1.48 in. (37.6 mm). Make the

1

base plate 25 in. (635 mm) wide and 1 /2 in. (38.1

mm) thick.

4. Design the anchor bolts

From the calculation in step 3, C 2.805B

2.805(24.3) 68.2 kips (303.4 kN); T 68.2 – 30

38.2 kips (169.9 kN); A s 38.2/14 – 2.73 sq.in.

2

1

(17.61 cm ). Refer to the AISC Manual. Use 2 /4-

in. (57.2-mm) anchor bolts, one on each side of the

2

flange. Then A s 3.02 sq.in. (19.48 cm ).

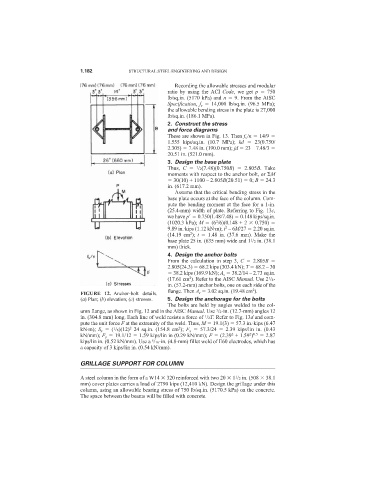

FIGURE 12. Anchor-bolt details.

(a) Plan; (b) elevation; (c) stresses. 5. Design the anchorage for the bolts

The bolts are held by angles welded to the col-

umn flange, as shown in Fig. 12 and in the AISC Manual. Use /2-in. (12.7-mm) angles 12

1

in. (304.8 mm) long. Each line of weld resists a force of /2T. Refer to Fig. 13d and com-

1

pute the unit force F at the extremity of the weld. Thus, M 19.1(3) 57.3 in.·kips (6.47

2

2

1

kN·m); S x ( /6)(12) 24 sq.in. (154.8 cm ); F x 57.3/24 2.39 kips/lin in. (0.43

2

2 0.5

kN/mm); F y 19.1/12 1.59 kips/lin in (0.29 kN/mm); F (2.39 + 1.59 ) 2.87

kips/lin in. (0.52 kN/mm). Use a /16-in. (4.8-mm) fillet weld of E60 electrodes, which has

5

a capacity of 3 kips/lin in. (0.54 kN/mm).

GRILLAGE SUPPORT FOR COLUMN

A steel column in the form of a W14 320 reinforced with two 20 1 /2 in. (508 38.1

1

mm) cover plates carries a load of 2790 kips (12,410 kN). Design the grillage under this

column, using an allowable bearing stress of 750 lb/sq.in. (5170.5 kPa) on the concrete.

The space between the beams will be filled with concrete.