Page 414 - Handbook of Energy Engineering Calculations

P. 414

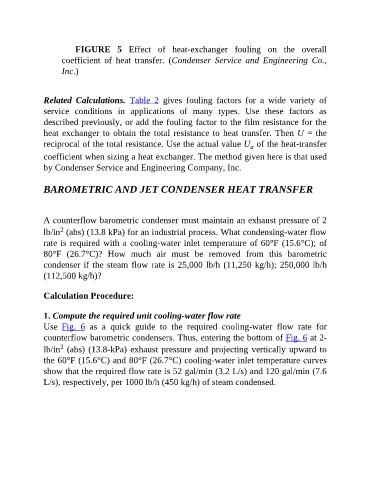

FIGURE 5 Effect of heat-exchanger fouling on the overall

coefficient of heat transfer. (Condenser Service and Engineering Co.,

Inc.)

Related Calculations. Table 2 gives fouling factors for a wide variety of

service conditions in applications of many types. Use these factors as

described previously, or add the fouling factor to the film resistance for the

heat exchanger to obtain the total resistance to heat transfer. Then U = the

reciprocal of the total resistance. Use the actual value U of the heat-transfer

a

coefficient when sizing a heat exchanger. The method given here is that used

by Condenser Service and Engineering Company, Inc.

BAROMETRIC AND JET CONDENSER HEAT TRANSFER

A counterflow barometric condenser must maintain an exhaust pressure of 2

2

lb/in (abs) (13.8 kPa) for an industrial process. What condensing-water flow

rate is required with a cooling-water inlet temperature of 60°F (15.6°C); of

80°F (26.7°C)? How much air must be removed from this barometric

condenser if the steam flow rate is 25,000 lb/h (11,250 kg/h); 250,000 lb/h

(112,500 kg/h)?

Calculation Procedure:

1. Compute the required unit cooling-water flow rate

Use Fig. 6 as a quick guide to the required cooling-water flow rate for

counterflow barometric condensers. Thus, entering the bottom of Fig. 6 at 2-

2

lb/in (abs) (13.8-kPa) exhaust pressure and projecting vertically upward to

the 60°F (15.6°C) and 80°F (26.7°C) cooling-water inlet temperature curves

show that the required flow rate is 52 gal/min (3.2 L/s) and 120 gal/min (7.6

L/s), respectively, per 1000 lb/h (450 kg/h) of steam condensed.