Page 175 - Handbook of Materials Failure Analysis

P. 175

5 Fracture Experiment on Tubular Specimens 171

W

a 0

Specimen

Fixture

Load

(a) (b)

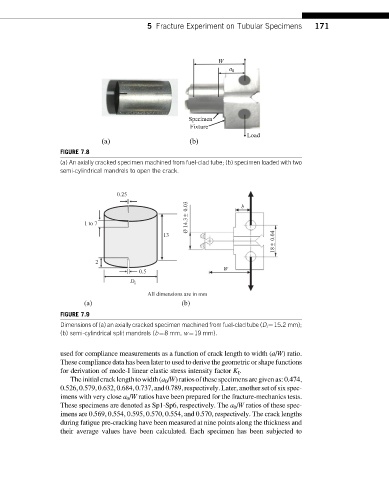

FIGURE 7.8

(a) An axially cracked specimen machined from fuel-clad tube; (b) specimen loaded with two

semi-cylindrical mandrels to open the crack.

0.25 b

Ø 14.3± 0.03

1 to 7

18± 0.04

13

2

W

0.5

D i

All dimensions are in mm

(a) (b)

FIGURE 7.9

Dimensions of (a) an axially cracked specimen machined from fuel-clad tube (D i ¼15.2 mm);

(b) semi-cylindrical split mandrels (b¼8 mm, w¼19 mm).

used for compliance measurements as a function of crack length to width (a/W)ratio.

These compliance data has been later to used to derive the geometric or shape functions

for derivation of mode-I linear elastic stress intensity factor K I .

Theinitialcracklengthtowidth(a 0 /W)ratiosofthesespecimensaregivenas:0.474,

0.526,0.579,0.632,0.684,0.737,and 0.789,respectively. Later, another set ofsix spec-

imens with very close a 0 /W ratios have been prepared for the fracture-mechanics tests.

These specimens are denoted as Sp1-Sp6, respectively. The a 0 /W ratios of these spec-

imens are 0.569, 0.554, 0.595, 0.570, 0.554, and 0.570, respectively. The crack lengths

during fatigue pre-cracking have been measured at nine points along the thickness and

their average values have been calculated. Each specimen has been subjected to