Page 180 - Handbook of Materials Failure Analysis

P. 180

176 CHAPTER 7 Investigation of failure behavior of tubular components

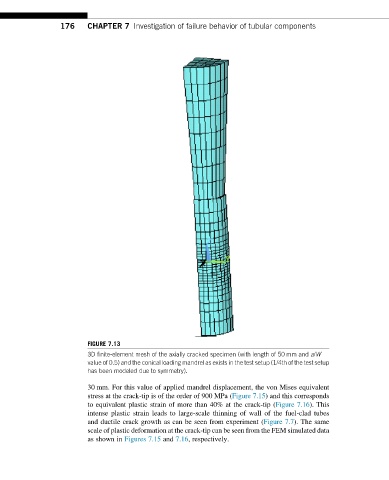

FIGURE 7.13

3D finite-element mesh of the axially cracked specimen (with length of 50 mm and a/W

value of 0.5) and the conical loading mandrel as exists in the test setup (1/4th of the test setup

has been modeled due to symmetry).

30 mm. For this value of applied mandrel displacement, the von Mises equivalent

stress at the crack-tip is of the order of 900 MPa (Figure 7.15) and this corresponds

to equivalent plastic strain of more than 40% at the crack-tip (Figure 7.16). This

intense plastic strain leads to large-scale thinning of wall of the fuel-clad tubes

and ductile crack growth as can be seen from experiment (Figure 7.7). The same

scale of plastic deformation at the crack-tip can be seen from the FEM simulated data

as shown in Figures 7.15 and 7.16, respectively.