Page 292 - Handbook of Materials Failure Analysis

P. 292

288 CHAPTER 12 A nonlocal damage-mechanics-based approach

B

F

B n

W

F

V LL

W

a

a 0

L = 4W

(a) (b) F

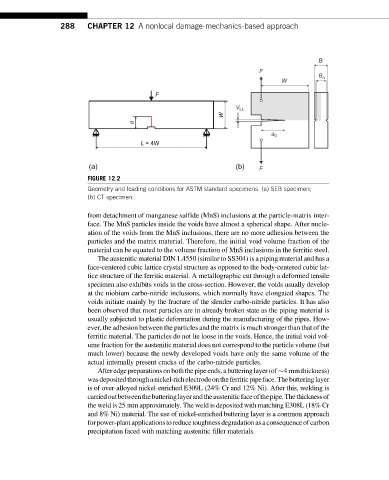

FIGURE 12.2

Geometry and loading conditions for ASTM standard specimens. (a) SEB specimen;

(b) CT specimen.

from detachment of manganese sulfide (MnS) inclusions at the particle-matrix inter-

face. The MnS particles inside the voids have almost a spherical shape. After nucle-

ation of the voids from the MnS inclusions, there are no more adhesion between the

particles and the matrix material. Therefore, the initial void volume fraction of the

material can be equated to the volume fraction of MnS inclusions in the ferritic steel.

The austenitic material DIN 1.4550 (similar to SS304) is a piping material and has a

face-centered cubic lattice crystal structure as opposed to the body-centered cubic lat-

tice structure of the ferritic material. A metallographic cut through a deformed tensile

specimen also exhibits voids in the cross-section. However, the voids usually develop

at the niobium carbo-nitride inclusions, which normally have elongated shapes. The

voids initiate mainly by the fracture of the slender carbo-nitride particles. It has also

been observed that most particles are in already broken state as the piping material is

usually subjected to plastic deformation during the manufacturing of the pipes. How-

ever, the adhesion between the particles and the matrix is much stronger than that of the

ferritic material. The particles do not lie loose in the voids. Hence, the initial void vol-

ume fraction for the austenitic material does not correspond to the particle volume (but

much lower) because the newly developed voids have only the same volume of the

actual internally present cracks of the carbo-nitride particles.

Afteredgepreparationsonboththepipeends,abutteringlayer(of 4 mmthickness)

wasdepositedthroughanickel-richelectrodeontheferriticpipeface.Thebutteringlayer

is of over-alloyed nickel-enriched E309L (24% Cr and 12% Ni). After this, welding is

carriedoutbetweenthebutteringlayerandtheausteniticfaceofthepipe.Thethicknessof

the weld is 25 mm approximately. The weld is deposited with matching E308L (18% Cr

and 8% Ni) material. The use of nickel-enriched buttering layer is a common approach

forpower-plantapplicationstoreducetoughnessdegradationasaconsequenceofcarbon

precipitation faced with matching austenitic filler materials.