Page 401 - Handbook of Materials Failure Analysis

P. 401

3 Stress-Corrosion Induced Failures 399

FIGURE 15.4

Water leakage in the firefighting pipe due to corrosion holes at the weld line and adjacent

to the weld line [37].

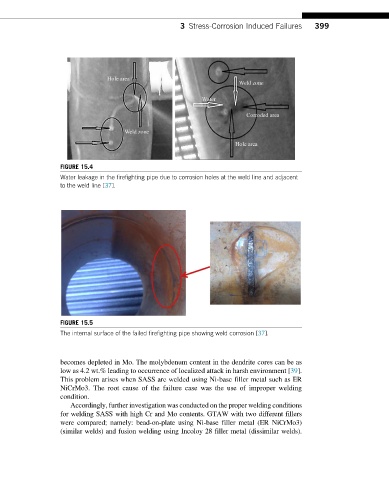

FIGURE 15.5

The internal surface of the failed firefighting pipe showing weld corrosion [37].

becomes depleted in Mo. The molybdenum content in the dendrite cores can be as

low as 4.2 wt.% leading to occurrence of localized attack in harsh environment [39].

This problem arises when SASS are welded using Ni-base filler metal such as ER

NiCrMo3. The root cause of the failure case was the use of improper welding

condition.

Accordingly, further investigation was conducted on the proper welding conditions

for welding SASS with high Cr and Mo contents. GTAW with two different fillers

were compared; namely: bead-on-plate using Ni-base filler metal (ER NiCrMo3)

(similar welds) and fusion welding using Incoloy 28 filler metal (dissimilar welds).