Page 167 - Handbook of Plastics Technologies

P. 167

THERMOSETS

THERMOSETS 3.37

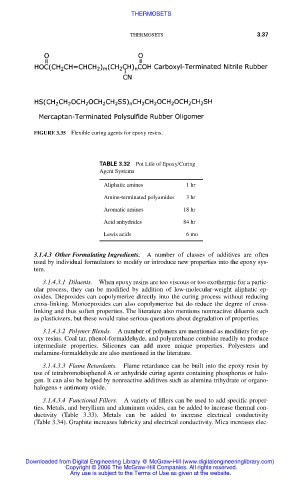

FIGURE 3.35 Flexible curing agents for epoxy resins.

TABLE 3.32 Pot Life of Epoxy/Curing

Agent Systems

Aliphatic amines 1 hr

Amine-terminated polyamides 3 hr

Aromatic amines 18 hr

Acid anhydrides 84 hr

Lewis acids 6 mo

3.1.4.3 Other Formulating Ingredients. A number of classes of additives are often

used by individual formulators to modify or introduce new properties into the epoxy sys-

tem.

3.1.4.3.1 Diluents. When epoxy resins are too viscous or too exothermic for a partic-

ular process, they can be modified by addition of low-molecular-weight aliphatic ep-

oxides. Diepoxides can copolymerize directly into the curing process without reducing

cross-linking. Monoepoxides can also copolymerize but do reduce the degree of cross-

linking and thus soften properties. The literature also mentions nonreactive diluents such

as plasticizers, but these would raise serious questions about degradation of properties.

3.1.4.3.2 Polymer Blends. A number of polymers are mentioned as modifiers for ep-

oxy resins. Coal tar, phenol-formaldehyde, and polyurethane combine readily to produce

intermediate properties. Silicones can add more unique properties. Polyesters and

melamine-formaldehyde are also mentioned in the literature.

3.1.4.3.3 Flame Retardants. Flame retardance can be built into the epoxy resin by

use of tetrabromobisphenol A or anhydride curing agents containing phosphorus or halo-

gen. It can also be helped by nonreactive additives such as alumina trihydrate or organo-

halogens + antimony oxide.

3.1.4.3.4 Functional Fillers. A variety of fillers can be used to add specific proper-

ties. Metals, and beryllium and aluminum oxides, can be added to increase thermal con-

ductivity (Table 3.33). Metals can be added to increase electrical conductivity

(Table 3.34). Graphite increases lubricity and electrical conductivity. Mica increases elec-

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2006 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.