Page 170 - High Power Laser Handbook

P. 170

138 Diode Lasers High-Power Diode Laser Arrays 139

Figure 6.5

Expansion-matched

mini-channel heat

sink. (Courtesy of

Curamik)

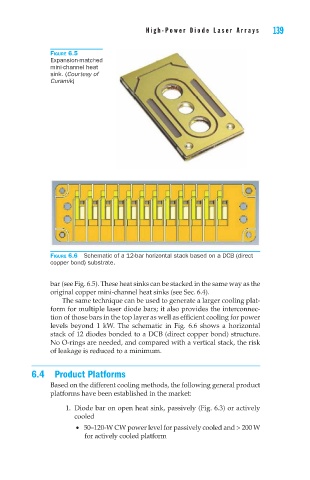

Figure 6.6 Schematic of a 12-bar horizontal stack based on a DCB (direct

copper bond) substrate.

bar (see Fig. 6.5). These heat sinks can be stacked in the same way as the

original copper mini-channel heat sinks (see Sec. 6.4).

The same technique can be used to generate a larger cooling plat-

form for multiple laser diode bars; it also provides the interconnec-

tion of those bars in the top layer as well as efficient cooling for power

levels beyond 1 kW. The schematic in Fig. 6.6 shows a horizontal

stack of 12 diodes bonded to a DCB (direct copper bond) structure.

No O-rings are needed, and compared with a vertical stack, the risk

of leakage is reduced to a minimum.

6.4 Product Platforms

Based on the different cooling methods, the following general product

platforms have been established in the market:

1. Diode bar on open heat sink, passively (Fig. 6.3) or actively

cooled

• 50–120-W CW power level for passively cooled and > 200 W

for actively cooled platform