Page 250 - How To Implement Lean Manufacturing

P. 250

228 Cha pte r F i f tee n

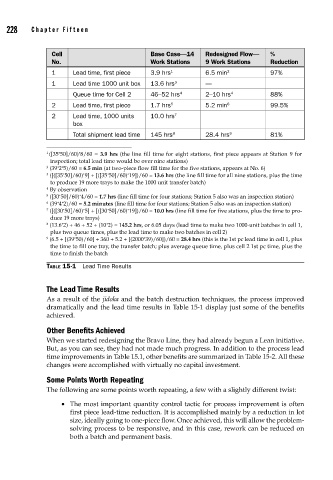

Cell Base Case—14 Redesigned Flow— %

No. Work Stations 9 Work Stations Reduction

1 Lead time, first piece 3.9 hrs 1 6.5 min 2 97%

1 Lead time 1000 unit box 13.6 hrs 3 —

Queue time for Cell 2 46–52 hrs 4 2–10 hrs 4 88%

2 Lead time, first piece 1.7 hrs 5 5.2 min 6 99.5%

2 Lead time, 1000 units 10.0 hrs 7

box

Total shipment lead time 145 hrs 8 28.4 hrs 9 81%

∗

∗

1 ([35 50]/60) 8/60 = 3.9 hrs (the line fill time for eight stations, first piece appears at Station 9 for

inspection; total lead time would be over nine stations)

∗ ∗

2 (39 2 5)/60 = 6.5 min (at two-piece flow fill time for the five stations, appears at No. 6)

∗

∗

∗

∗

3 ([([35 50]/60) 9] + [([35 50]/60) 19])/60 = 13.6 hrs (the line fill time for all nine stations, plus the time

to produce 19 more trays to make the 1000 unit transfer batch)

4 By observation

∗

∗

5 ([30 50]/60) 4/60 = 1.7 hrs (line fill time for four stations; Station 5 also was an inspection station)

∗ ∗

6 (39 4 2)/60 = 5.2 minutes (line fill time for four stations; Station 5 also was an inspection station)

∗

∗

∗

∗

7 ([([30 50]/60) 5] + [([30 50]/60) 19])/60 = 10.0 hrs (line fill time for five stations, plus the time to pro-

duce 19 more trays)

∗

∗

8 (13.6 2) + 46 + 52 + (10 2) = 145.2 hrs, or 6.05 days (lead time to make two 1000-unit batches in cell 1,

plus two queue times, plus the lead time to make two batches in cell 2)

∗

∗

9 (6.5 + [(39 50)/60] + 360 + 5.2 + [(2000 39)/60])/60 = 28.4 hrs (this is the 1st pc lead time in cell 1, plus

the time to fill one tray, the transfer batch; plus average queue time, plus cell 2 1st pc time, plus the

time to finish the batch

TABLE 15-1 Lead Time Results

The Lead Time Results

As a result of the jidoka and the batch destruction techniques, the process improved

dramatically and the lead time results in Table 15-1 display just some of the benefits

achieved.

Other Benefits Achieved

When we started redesigning the Bravo Line, they had already begun a Lean initiative.

But, as you can see, they had not made much progress. In addition to the process lead

time improvements in Table 15.1, other benefits are summarized in Table 15-2. All these

changes were accomplished with virtually no capital investment.

Some Points Worth Repeating

The following are some points worth repeating, a few with a slightly different twist:

• The most important quantity control tactic for process improvement is often

first piece lead-time reduction. It is accomplished mainly by a reduction in lot

size, ideally going to one-piece flow. Once achieved, this will allow the problem-

solving process to be responsive, and in this case, rework can be reduced on

both a batch and permanent basis.