Page 179 - Industrial Power Engineering and Applications Handbook

P. 179

Static controls and braking of motors 6/159

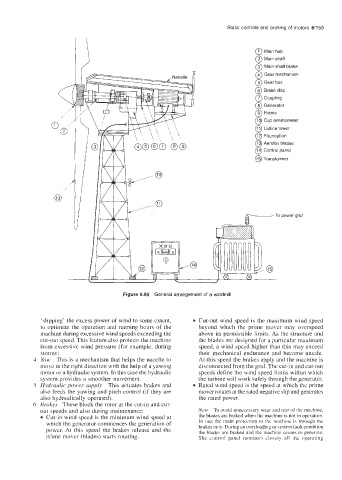

@ Main hub

@ Main shaft

@ Main shaft brake

@ Gear mechanism

0 box

Gear

@ Brake disc

0 Coupling

@) Generator

@ Frame

@ cup anemometer

@) Lattice tower

@ Foundation

@ Aerofoil blades

@ Control panel

@ Transformer

power grid

Figure 6.65 General arrangement of a windmill

'slipping' the excess power of wind to some extent, Cut-out wind speed is the maximum wind speed

to optimize the operation and running hours of the beyond which the prime mover may overspeed

machine during excessive wind speeds exceeding the above its permissible limits. As the structure and

cut-out speed. This fcature also protects the machine the blades are designed for a particular maximum

from excessive wind pressure (for example, during speed, a wind speed higher than this may exceed

storms ). their mechanical endurance and become unsafe.

4 Knis This is a mechanism that helps the nacelle to At this speed the brakes apply and the machine is

move in the right direction with the help of a yawing disconnected from the grid. The cut-in and cut-out

motor or a hydraulic system. In this case the hydraulic speeds define the wind speed limits within which

system provides a smoother movement. the turbine will work safely through the generator.

5 Hydruulic power supply This actuates brakes and Rated wind speed is the speed at which the prime

also feeds the yawing and pitch control (if they are mover rotates at the rated negative slip and generates

also hydraulically operated). the rated power.

6 Brnkes These block the rotor at the cut-in and cut-

out speeds and also during maintenance: Note To avoid unnecessary wear and tear of the machine.

Cut-in wind speed is the minimum wind speed at the blades are braked when the machine is not in operation.

which the generator commences the generation of In fact the main protcction to the rriiichine is through the

power. At this speed the brakes release and the brakes only. During an overloading or system fault condition

the blades are braked and the machine ceases to generate.

prime mover (blades) starts rotating. The control panel monitors closely all the operating